Predictive vs Preventive Maintenance Software: A Comparative Analysis and Strategic Trends 2025-2030

Table of contents

- The Evolution of Industrial Maintenance: From Reactive to Predictive

- Preventive Maintenance

- What is PM? Definition and principles

- Key features of PM software and approaches

- Advantages and disadvantages of PM

- Advantages

- Common PM implementation challenges

- PM success stories

- Predictive Maintenance

- What is PdM? Definition and principles

- How PdM software works: leveraging IoT, AI/ML, and advanced analytics

- Enhanced features and unique capabilities

- Advantages and disadvantages of PdM

- Advantages

- Common PdM implementation challenges

- Real-world PdM success stories

- Prescriptive Maintenance (RxM)

- Predictive vs. Preventive: A Strategic Comparison

- Strategic Decision-Making: Choosing the Optimal Approach

- When to choose PM

- When to choose PdM

- The value of a hybrid approach

- The Financial imperative: ROI of maintenance software

- Emerline Case Study: Revolutionizing Maintenance for a Leading Iron and Mining Company

- Strategic Trends in Maintenance: A Look Towards 2025-2030

- Conclusion

The Evolution of Industrial Maintenance: From Reactive to Predictive

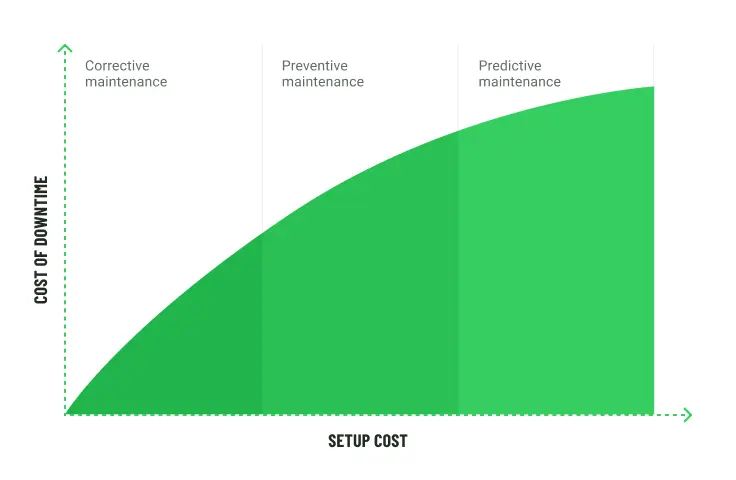

Historically, industrial maintenance has been predominantly reactive. Imagine your car running until something breaks down. Only then do you take it to the shop. While seemingly simple, this approach leads to unplanned downtimes, production halts, and often higher repair costs due to catastrophic failures.

The first significant shift towards proactive strategies came with Preventive Maintenance (PM). This approach introduced the concept of scheduled maintenance to prevent problems. Think of it like your car's scheduled service every 6,000 miles or once a year, even if it seems to be running perfectly. This significantly reduced unexpected breakdowns.

The latest and most advanced evolution in maintenance strategy is Predictive Maintenance (PdM). Using cutting-edge technologies, PdM goes beyond fixed schedules, anticipating needed maintenance. It's like your car's sensors telling you, "Your brake pads will wear out in 300 miles; it's time to schedule a replacement." This approach allows for "just-in-time" interventions, optimizing service time. "This is where the future of efficiency lies."

Modern maintenance software, commonly known as CMMS (Computerized Maintenance Management System) or EAM (Enterprise Asset Management), has become indispensable. These platforms serve as central digital hubs for managing various maintenance operations. Their implementation is critical for transitioning from inefficient manual processes to optimizing efficiency, extending asset lifespans, and significantly reducing overall maintenance costs.

Imagine a massive production facility with tens of thousands of complex equipment units constantly at risk of failure. This isn't just an inconvenience; it's a catastrophe capable of halting the entire production process, leading to colossal losses and damaging the company's reputation. In such a situation, implementing intelligent predictive or prescriptive software helps predict potential equipment failures long before they occur and offers optimal solutions to prevent them, minimizing downtime and avoiding other risks. – Eric Johnson, Emerline

| Maintenance Strategy | Intervention Time | Primary Goal | Key Characteristics | Advantages | Disadvantages |

| Reactive | After failure | Fix breakdown | Unplanned downtime, emergency repairs | Low initial costs, simplicity | High long-term costs, increased unplanned downtime, reduced asset lifespan, safety risks, less predictable budgets |

| Preventive | On schedule | Prevent failure | Fixed schedules, proactive | Minimizes unexpected downtime, reduces costly repairs, extends equipment lifespan, lowers accident risk | Higher planning costs, potential for over-maintenance or missing impending failures |

| Predictive | Before failure | Predict and optimize | Data management, AI/ML, IoT, proactivity | Reduced downtime through early detection, increased cost-effectiveness, extended equipment lifespan, improved resource allocation, enhanced safety | High initial investment, requires skilled teams |

The choice between these approaches directly impacts equipment reliability and profitability. Maintenance is no longer just an expense; it becomes a strategic investment that supports production continuity, enhances quality, and improves overall business profitability. It redefines maintenance from a necessary evil into a competitive advantage.

Preventive Maintenance

What is PM? Definition and principles

Preventive Maintenance (PM) is a proactive strategy characterized by regularly scheduled maintenance tasks designed to reduce the likelihood of equipment failure and extend asset life. Think of it like your annual physical exam: you get checked on a schedule to find potential problems before they become serious, even if you feel fine now. Its core principle relies on "time-based" or "usage-based" triggers (e.g., service every six months or after a certain number of operating hours). The methodology follows standardized checklists for routine inspections, calibration, cleaning, lubrication, and planned component repair or replacement.

Key features of PM software and approaches

PM software, often integrated into CMMS, provides:

- Reliable asset record keeping.

- Intuitive scheduling calendars.

- Automated alerts and notifications.

- Customizable inspection checklists with step-by-step instructions.

- Work order creation and tracking.

- Automated reporting for performance monitoring.

Advantages and disadvantages of PM

Advantages

- Reduced unplanned downtime: Significantly minimizes unexpected equipment failures.

- Extended equipment lifespan: Regular maintenance reduces wear and tear.

- Improved safety and compliance: Well-maintained equipment is inherently safer and helps meet regulatory standards.

- Predictable budgeting: Shifts maintenance costs from unpredictable, large-scale reactive repairs to more manageable, planned expenses.

- Cost savings: Can yield 12-18% cost savings compared to a purely reactive approach.

- Enhanced energy efficiency: Regularly maintained equipment operates at peak efficiency.

Common PM implementation challenges

Despite its advantages, PM implementation comes with several challenges:

- Risk of over-maintenance: The primary drawback. "This is like changing perfect tires just because the 'schedule says so,' not because they're worn out." Such "over-maintenance" wastes time, labor, and spare parts, consuming valuable resources.

- Scheduled downtime: While PM prevents unscheduled failures, it still requires planned downtime for maintenance tasks, which can disrupt production.

- Resource requirements: Implementing a comprehensive PM program demands dedicated time and resources, which can be challenging for organizations with limited budgets or staff.

- Resistance to change: Shifting from a "fix-it-when-it-breaks" mentality to a proactive approach might be met with resistance from employees accustomed to old routines.

- Scalability challenges: As the number of assets increases, manually managing and optimizing PM schedules can become highly complex. Without a robust software system, it might be challenging to identify which areas require PM and track progress, leading to missed tasks or inefficiencies.

PM success stories

- Uline Warehouses (Logistics Industry, USA): Implementing intelligent monitoring systems significantly reduced emergencies related to warehouse equipment and lowered energy consumption through optimized workflows.

- Automotive Parts Supplier (Automotive Industry, USA): Predictive analytics reduced conveyor system incidents by 48% and overall equipment downtime by 24%. This significantly boosted production efficiency and lowered repair costs.

- Allagash Brewing Company (Food & Beverage Industry, USA): Replacing multiple outdated systems with Limble's all-in-one CMMS helped Allagash cut unplanned work orders by over 40%, streamline maintenance operations, and boost task completion rates by 200%, supporting their rapid growth and sustainability goals.

PM is ideal for assets with predictable failure modes or when potential failure costs are manageable. It's an excellent starting point for proactive maintenance, offering a low barrier to entry. Successful PM implementation lays the groundwork for more advanced strategies like Predictive Maintenance.

Predictive Maintenance

What is PdM? Definition and principles

Predictive Maintenance (PdM) is an advanced maintenance strategy that uses real-time data analysis to accurately forecast when maintenance is due, thereby preventing equipment failure before it actually occurs. Its core principle is "condition-based maintenance." Unlike fixed PM schedules, PdM triggers maintenance actions only when specific indicators, such as sensor data showing declining performance or impending failure, are detected. The methodology focuses on forecasting failure "just-in-time" and optimizing intervention timing.

How PdM software works: leveraging IoT, AI/ML, and advanced analytics

At the heart of PdM is continuous data collection, which heavily relies on Internet of Things (IoT) sensors installed on equipment. These sensors monitor various parameters like vibration, temperature, acoustic emissions, and oil quality in real time. Historical maintenance records also serve as a crucial input for building predictive models.

As equipment operates, sensors continuously collect readings. The PdM system monitors these inputs for fluctuations or patterns that deviate from established normal parameters, indicating potential issues. The vast amounts of collected data are then fed into advanced analytical systems that utilize Machine Learning (ML) algorithms. These algorithms analyze data to detect subtle patterns, anomalies, and trends signaling impending equipment failures. Importantly, these models learn and improve their prediction accuracy over time by continuously processing new and historical data.

Based on this analysis, the system develops predictive models that forecast when an asset will likely fail or require service. When a potential issue is identified, the system automatically triggers alerts and generates work orders in the CMMS, notifying maintenance teams to schedule timely repairs before a breakdown occurs. Continuous improvement is key: by consistently collecting and analyzing data, refining algorithms, and incorporating feedback from maintenance actions, organizations can hone their PdM strategies to enhance asset reliability and efficiency further.

PdM is more than just software; it's a complex, data-driven ecosystem. Its effectiveness depends on a seamless, high-quality data flow from physical assets to analytical systems and operational teams. This implies that organizations must invest in PdM software and the underlying data infrastructure, including robust sensors, reliable connectivity, efficient data management, and the necessary analytical capabilities to unlock their transformative potential. Without a strong data foundation, PdM remains an unfulfilled promise.

Enhanced features and unique capabilities

- Customizable dashboards: Intuitive, customizable interfaces, provide maintenance teams and managers with real-time visibility into equipment health, Key Performance Indicators (KPIs), and maintenance status.

- Predictive modeling and algorithms: Beyond basic anomaly detection, PdM software utilizes sophisticated algorithms, including supervised and unsupervised learning, regression models, time-series analysis, and survival analysis, to precisely forecast remaining useful life and potential failure points.

- Digital twins: Virtual, real-time replicas of physical assets. "Imagine a virtual model of your car that exactly mirrors the real one's behavior, fed by sensor data. You can test scenarios on it without touching the actual car." Connected to actual equipment via data streams, digital twins enable continuous monitoring, AI-powered analytics, and the ability to simulate various operating conditions and maintenance scenarios without impacting the physical asset. They offer more profound insights into equipment performance and optimize asset lifecycle management. The digital twin market is projected to reach $73.5 billion by 2027.

- Edge computing: "This is like a smart system right in the machine itself analyzing data and immediately signaling a problem, without sending all the data to a central server." This technology allows data processing directly at the source (at the "edge" of the network), minimizing latency. This enables real-time monitoring and immediate responses to potential issues, which are critical in time-sensitive industrial environments. It also reduces bandwidth requirements and enhances data security by processing sensitive data locally.

- Seamless integration with existing systems (CMMS/ERP): Effective PdM software seamlessly integrates with existing ERPs, Enterprise Asset Management (EAM), and CMMS systems. This ensures streamlined operations, consistent data exchange across the organization, and a unified view of asset health and maintenance activities.

- Predictive Maintenance as a service (PdMaaS): "You essentially 'rent' the predictive maintenance service from a third-party provider, without having to buy all the complex system components yourself." This model allows companies to adopt PdM solutions without significant upfront capital investments. PdMaaS providers remotely handle data analytics, asset monitoring, and issue alerts, making advanced capabilities more accessible.

Advantages and disadvantages of PdM

Advantages

- Significant cost savings: Compared to reactive maintenance, PdM can reduce maintenance costs by 5-10%.

- Increased uptime and asset availability: It drastically cuts unexpected failures by up to 55%, increases equipment uptime by 30%, and can reduce nuplanned downtime by up to 50%. McKinsey Global Institute reports that PdM adoption can lead to $240-627 billion in cost savings in manufacturing alone.

- Extended equipment lifespan: By identifying and addressing minor issues early, PdM prevents premature wear, significantly prolonging asset life.

- Optimized maintenance scheduling: Maintenance is performed only when truly necessary, leading to highly efficient labor and resource utilization.

- Improved inventory management: Parts are replaced precisely when needed, reducing the need for excessive spare parts inventory, minimizing overstocking, and lowering associated storage costs.

- Enhanced safety: By identifying potential equipment hazards before they lead to breakdowns, PdM significantly boosts workplace safety and reduces the risk of accidents.

- Increased production/productivity: Enhanced reliability and reduced downtime directly translates to higher output, with studies showing 20-25% increases in production and AI tools boosting labor productivity by 5-20%.

- Exceptional return on investment (ROI): PdM offers a potential ROI 10 times greater than its initial costs, making it a highly attractive investment.

Common PdM implementation challenges

- High initial investments: Requires substantial investments in IoT sensors, advanced analytical software, and specialized staff training.

- Dependence on data quality: PdM effectiveness hinges entirely on accurate, high-quality real-time data. Inconsistencies, inaccuracies, or incomplete data can jeopardize forecasts and lead to false alarms. The practical difficulties involve aggregating data from disparate sources (various sensor types, legacy systems), cleaning it from noise and gaps, and ensuring its consistency and timeliness. Poor data quality is a frequent source of prediction errors and distrust in the system.

- Big Data management: Managing the immense volume of generated data (storage, bandwidth, computational resources) poses a considerable challenge.

- Integration complexity: Many companies operate with a patchwork of legacy systems, making seamless integration of new PdM software and sensor data a significant technical hurdle.

- Need for specialized skills: PdM systems demand a workforce with specialized skills for managing IoT devices, interpreting complex data, and making informed decisions based on prognostic data. This includes data scientists, machine learning engineers, experienced reliability engineers who can interpret AI outputs within the context of equipment operations, and technicians trained to work with new tools and procedures. Finding and retaining such talent is a significant concern.

- Resistance to personnel: Employees accustomed to traditional maintenance methods might resist adopting new technologies and processes, slowing adoption.

- Cybersecurity risks: The increasing interconnectedness of systems (IoT, cloud, AI) creates new vulnerabilities, making PdM systems potential targets for cyberattacks if sensitive operational data is not adequately secured. Robust security measures are paramount.

- Technological and organizational complexity: PdM is inherently more complex than preventive maintenance due to its reliance on advanced technologies and data science. It often necessitates a significant technological overhaul and a shift in organizational mindset.

Real-world PdM success stories

Here are several examples of successful Predictive Maintenance implementations across various industries:

- General Motors (automotive, USA): By implementing PdM with IoT sensors and AI to monitor assembly line robots, GM achieved a 15% reduction in unplanned downtime and saved $20 million annually in maintenance costs. This demonstrates a significant financial impact from optimizing manufacturing processes.

- Frito-Lay (food and beverage, USA): Using a predictive system, this company successfully minimized scheduled downtime to 0.75% and limited unscheduled failures to 2.88%. A notable success was preventing the failure of a critical PC combustion blower motor, which would have severely impacted potato chip production.

- Tetra Pak (packaging industry, Switzerland): Implemented remote monitoring and cloud computing to service global clients. This allowed them to predict machine failures, saving one dairy company over 140 hours of downtime and reducing the need for costly specialist travel.

- Rolls-Royce (aerospace industry, UK): Successfully reduced engine maintenance costs by 30% through the use of IoT sensor data and digital twins. This example highlights the synergy of advanced technologies in achieving tangible economic results.

ThyssenKrupp (industrial manufacturing, Germany): Improved service reliability by 50% by implementing PdM solutions with IoT connectivity. - Shell (oil and gas industry, Netherlands/UK): Achieved a 20% reduction in equipment downtime by implementing sensor-based predictive analytics.

Prescriptive Maintenance (RxM)

While this document primarily focuses on PdM, it's important to note the emerging role of Prescriptive Maintenance (RxM). Where PdM tells you when an asset might fail, RxM goes a step further, advising what action to take and when to optimize performance and prevent future issues. RxM leverages AI and advanced analytics to suggest specific maintenance actions, order parts, schedule technicians, and even automate minor repairs, providing truly optimized, actionable insights. This represents the next frontier beyond predictive capabilities.

Predictive vs. Preventive: A Strategic Comparison

Strategic Decision-Making: Choosing the Optimal Approach

When to choose PM

PM is often ideal for assets with predictable failure modes (filters, lubricants) or when the cost of potential failure is manageable. It's an excellent starting point for proactive maintenance with a low barrier to entry.

When to choose PdM

PdM is best suited for high-value, mission-critical assets where unexpected downtime is extremely costly (e.g., main production lines). It's effective when failures can be accurately predicted. Choose PdM to maximize uptime and reduce costs. It's a natural fit for companies with existing IoT infrastructure or a strong commitment to digital transformation.

The value of a hybrid approach

In practice, many successful organizations adopt a blended strategy. They apply PM to less critical assets and reserve resource-intensive PdM for high-value assets. This hybrid model allows for efficient cost and resource management while choosing the "right maintenance strategy for each asset" based on its criticality and failure modes.

The choice of strategy depends on an organization's risk tolerance and initial investment capabilities. Companies with limited capital might start with PM. Industries with critical operations (manufacturing, energy, aerospace), where even a minute of downtime translates to thousands of dollars in losses, will justify higher initial investments in PdM for its superior risk mitigation capabilities and greater long-term ROI potential.

The Financial imperative: ROI of maintenance software

Understanding the financial returns on maintenance software investments requires a comprehensive approach. From an expert perspective, Return on Investment (ROI) is the most indicative measure of investment effectiveness, as it quantitatively reflects the net profit from an investment relative to its cost. For maintenance software, ROI is driven by several key factors:

- Reduced downtime: Minimizing unplanned outages directly boosts productivity.

- Lower maintenance costs: Optimizing labor, reducing emergency repairs, and streamlining equipment and inventory expenses.

- Extended asset lifespan: Proactive maintenance postpones the need for costly equipment replacements.

- Increased productivity: Reliable operations lead to consistent output.

- Improved inventory management: Optimized spare parts stock reduces holding costs and minimizes shortages.

- Enhanced Safety: Fewer equipment failures lead to a safer work environment.

- Energy Efficiency: Well-maintained equipment operates more efficiently, lowering consumption.

Experience shows that both preventive and predictive maintenance yield high ROI. For instance, implementing Preventive Maintenance can deliver a striking ROI of 545%. Meanwhile, Predictive Maintenance offers even greater potential – an ROI 10 times its initial cost, while reducing operational expenses by 25-30% compared to a reactive approach. Custom development can amplify this ROI by tailoring functionalities to specific business processes, eliminating bottlenecks, and unlocking complete optimization potential unavailable in off-the-shelf solutions.

Often, though it's not immediately obvious, custom software proves more cost-effective in the long run," states Eric Johnson, Emerline. Initial investments in standard "off-the-shelf" solutions may seem lower, but they often incur additional costs for adapting to unique processes, integrating with existing infrastructure, and licensing unused features. "Custom development, conversely, allows for creating a system perfectly aligned with business needs, minimizing over-maintenance, enhancing employee efficiency, and ensuring seamless integration, thereby unlocking maximum ROI over a 3-5 year horizon and beyond.

Emerline offers its expert services for an accurate investment assessment and to choose the most suitable solution, whether off-the-shelf, custom, or hybrid. We conduct comprehensive audits and analyses of your current processes and needs to help you make an informed strategic decision and ensure maximum investment return.

Emerline Case Study: Revolutionizing Maintenance for a Leading Iron and Mining Company

"Imagine a massive production facility where tens of thousands of complex equipment units are constantly at risk of failure. This isn't just an inconvenience; it's a catastrophe capable of halting the entire production process, leading to colossal losses and damaging the company's reputation. In such a situation, implementing intelligent predictive or prescriptive software allows you to predict potential equipment failures long before they occur and suggest optimal solutions to prevent them, minimizing downtime and avoiding other risks." – Eric Johnson, Emerline.

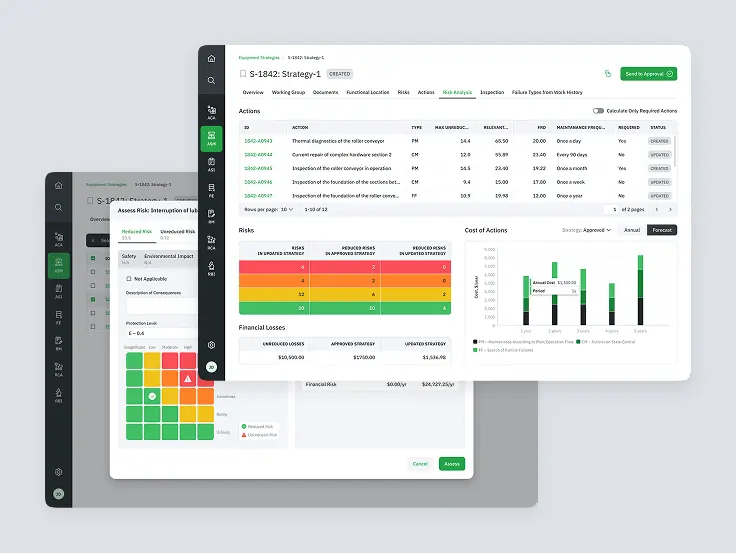

Emerline partnered with a leading iron and mining company that was facing significant production losses due to equipment failures. Initially seeking a preventive maintenance platform, the client's legacy ERP system proved incompatible, necessitating a custom approach. We undertook a complex data migration of five years of records to a modern SAP S/4HANA environment while developing and integrating a full-scale predictive maintenance solution. This custom platform, built on an Agile methodology and leveraging Reliability-Centered Maintenance (RCM) principles, provided advanced features like innovative risk assessment tools, real-time performance dashboards, automated strategy implementation, and 'Miro-like' root cause analysis, all seamlessly integrated with SAP S/4HANA and a robust, customizable identity access management system.

This strategic shift yielded remarkable results for the client. They achieved a 40% reduction in repair costs and a 3% increase in equipment reliability, significantly enhancing operational efficiency and transparency. The high-performance platform processes data in under a second and has since been adopted by over 1,000 users across five client companies. It manages 1.5 million equipment spots and enables the development of 20,000 maintenance strategies. This success story highlights Emerline's capability to deliver complex, custom-built predictive maintenance solutions that drive measurable ROI and transform industrial operations.

Strategic Trends in Maintenance: A Look Towards 2025-2030

The industrial maintenance landscape is rapidly evolving, bringing significant changes in the coming years. Here are the key trends shaping maintenance strategies from 2025 to 2030:

- Hyper-automation and autonomous systems: We're seeing a shift towards fully automated monitoring and maintenance processes. Sensors and AI will predict problems and trigger robotic or autonomous systems to perform minor repairs or adjustments without human intervention.

- Deeper integration with ERP and MES: Maintenance systems will integrate even more tightly with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This will create a single source of truth for all operational activities, providing complete transparency from order to production and maintenance.

- Generative AI in decision-making: Generative AI will be used not just for data analysis but also to generate optimal maintenance strategies, create detailed work orders, train new technicians, and even simulate equipment behavior in various scenarios.

- Enhanced role of "digital twins": Digital twins will become pervasive, allowing for the modeling and optimization of asset lifecycles, predicting wear and tear with unprecedented accuracy, and testing maintenance strategies in a virtual environment before real-world application.

- Immersive technologies (AR/VR/MR) for technicians: Augmented and mixed reality will become standard tools for engineers and field technicians. They will receive interactive instructions overlaid on real equipment, expert remote support, and access to critical data in real-time, boosting repair accuracy and speed.

- Cybersecurity as a top priority: With the increasing interconnectedness of systems (IoT, cloud, AI), cybersecurity threats are growing significantly. Protecting operational data and critical infrastructure will become paramount, demanding continuous investment in robust security systems and protocols.

- Sustainable maintenance: There will be a growing emphasis on environmental considerations. Maintenance optimization will focus on cost reduction and minimizing the carbon footprint, lowering energy consumption, and reducing waste through extended equipment life and more efficient resource use.

These trends point to a future where maintenance will be fully intelligent, autonomous, and deeply integrated into the enterprise's overall digital ecosystem, transforming it from a cost center into a strategic asset for sustainable growth and enhanced competitiveness.

Conclusion

The choice between preventive and predictive maintenance software is not merely a technical decision; it's a strategic one. Each strategy offers unique advantages, challenges, and varying financial implications.

Preventive Maintenance (PM) software is a reliable foundation for proactive care, offering predictability and significant cost savings compared to reactive approaches. It's relatively simple to implement and can yield impressive ROI. However, its time- or usage-based nature can lead to "over-maintenance," resulting in inefficiencies. Nevertheless, successful PM implementation lays the crucial groundwork for more advanced strategies by fostering a proactive mindset and foundational data management processes.

Predictive Maintenance (PdM) software represents the cutting edge of asset management, leveraging IoT sensors, AI/ML, and advanced analytics to forecast failures "just-in-time." This significantly reduces unplanned downtime, extended asset lifespans, and optimized resource utilization, offering a potential ROI 10 times its initial cost. PdM is particularly valuable for high-value, mission-critical assets where downtime is exceedingly costly. However, its implementation comes with higher initial costs, significant data quality and management challenges, a need for specialized personnel, and increased cybersecurity risks. PdM implementation often acts as a catalyst for broader digital transformation, demanding infrastructure modernization and the development of a data-driven culture.

Ultimately, the optimal approach often lies in a hybrid strategy, tailored to specific assets and operational needs. Organizations must carefully weigh asset criticality, failure modes, risk tolerance, and investment capabilities. PM can be an ideal starting point for less critical assets or those new to proactive maintenance. For high-value, mission-critical assets where minimal downtime is unacceptable, investing in PdM is justified by its superior risk mitigation capabilities and higher long-term ROI. When making this decision, enterprises should conduct a thorough Return on Investment (ROI) analysis to understand the actual financial returns.

Understanding these metrics empowers organizations to make informed decisions that optimize maintenance operations and contribute to overall business profitability and competitiveness. Moreover, a successful transition to advanced maintenance strategies like PdM often requires significant organizational change management and a clear digital transformation roadmap to ensure technological capabilities match operational readiness and skilled talent.

Published on Jul 28, 2025