Digital Twins: Modeling the Future of Manufacturing

Table of contents

- What is a Digital Twin?

- Key components: Digital Master, Digital Shadow, and their intelligent linking

- Varieties of digital twins in manufacturing

- Revolutionary Benefits of Digital Twins in Manufacturing

- Increased operational efficiency and productivity

- Cost reduction and resource optimization

- Predictive maintenance and downtime reduction

- Enhanced product quality

- Contribution to sustainable development

Key Use Cases of Digital Twins- Product design and development

- Manufacturing process and schedule optimization

- Predicting equipment failures and proactive maintenance

- Virtual testing and scenario simulation

- Integration with IoT and Artificial Intelligence: Combo for Smart Manufacturing

- How IoT provides real-time data

- The role of AI and Machine Learning in data analysis and decision-making

- The feedback mechanism between the physical and virtual worlds

- Digital Twin Market: Projected Growth and Outlook

- Current market size and growth forecasts

- Key growth drivers

- Digital Twins: Changing the Risk Profile of Innovation

- Conclusion

Modern manufacturing stands at the cusp of profound transformation, driven by Industry 4.0 technologies. At the center of these changes is the digital twin. This is not just a 3D model, but a dynamic, "living" virtual copy of a real object, process, or system. By using real-time data from sensors, a digital twin allows you to predict, control, and optimize the performance of its physical counterpart.

The concept of digital twins, which originated in the early 2000s, was initially linked to product lifecycle management. Over time, it has expanded significantly to encompass entire systems and manufacturing processes.

This technology is becoming more and more popular thanks to the Industry 4.0 revolution, which emphasizes interconnectivity, automation, and the use of real-time data. Companies are actively implementing digital twins to create more flexible, efficient, and adaptable production environments.

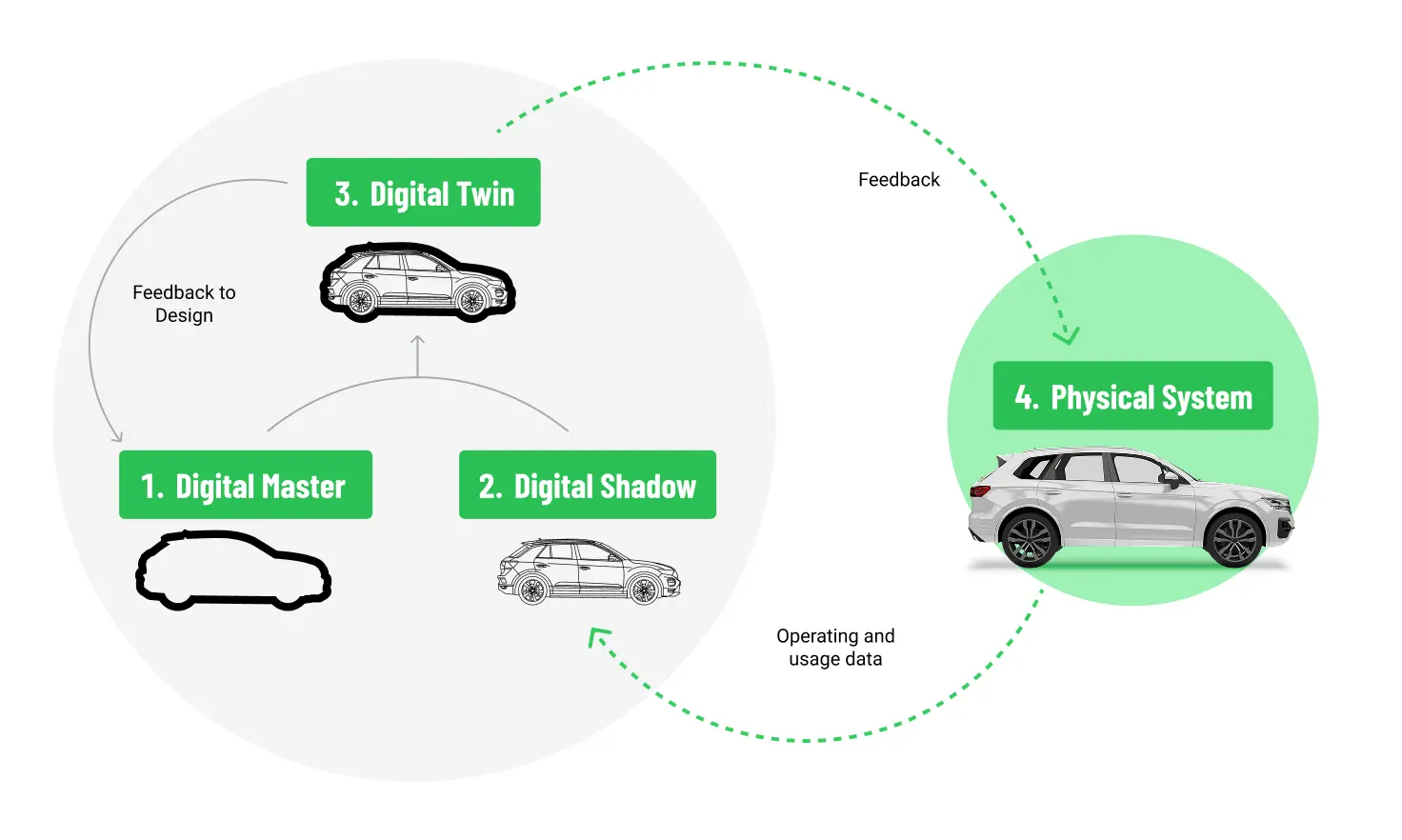

Digital twin of a car

Digital twin of a car

Digital twins represent more than just a new technology; they are a new approach to manufacturing. This technology enables a transition from reactive management to proactive foresight, from isolated processes to an integrated ecosystem. The ability to simulate and optimize processes before their physical implementation fundamentally changes how manufacturing is managed, enhancing efficiency, scalability, and innovation.

The power of digital twins comes from their integration with other Industry 4.0 technologies. For example, the IoT provides the data, and AI analyzes it to predict the future. Without this kind of teamwork, a digital twin would remain a static model.

It allows you to compare the "ideal" model (master) with real-world behavior (shadow), identify deviations, and continuously improve processes and future products. This makes digital twins the foundation of "smart" manufacturing.

What strikes me most is how digital twins shift us from reacting to problems to predicting and even shaping the future. They create a constant, intelligent feedback loop between the ‘master’—our intended design—and the ‘shadow’—a live digital reflection of what’s actually happening. By continuously analyzing deviations and feeding insights back into the model, we move from reactive fixes to proactive innovation. That’s what drives true transformation. - Vitali Usau, Head of Innovation and Mobile, Emerline

What is a Digital Twin?

A digital twin is a virtual representation of a physical object, process, or system. Its purpose is to observe, analyze, simulate, and optimize products or systems throughout their lifecycle. In manufacturing, a digital twin can range from a simple graphical representation of equipment data to a complex simulation model of an entire production line.

Key components: Digital Master, Digital Shadow, and their intelligent linking

The architecture of a digital twin comprises three core components that work in close interrelation:

- Digital Master: This component contains models of all relevant physical objects or processes. It represents the "ideal" or "designed" version, including data on geometry, behavior, functions, and other properties of products, machines, or processes. It represents what is expected from the system.

- Digital Shadow: In contrast to the master, the digital shadow represents the actual state of the physical object. It consists of data collected throughout the system's lifecycle, such as operational status and process data recorded by sensors. The digital shadow captures real-world characteristics and variations of each unique object.

- Intelligent linking: The true value of a digital twin lies in the intelligent linking between the digital master and the digital shadow. This bidirectional connection allows continuous data synchronization between the physical and digital worlds. For example, comparing master and shadow data enables prediction of the optimal time for maintenance or deriving significant improvement potential for future product generations, providing feedback to the design process.

This intelligent linking is the fundamental element that transforms a static model into a dynamically evolving and self-optimizing tool. Without this bidirectional connection, a digital twin would merely be an advanced simulation - and not a system capable of continuous learning, adapting to real-world conditions, and predicting the future, which is the key to its advantage. The distinction between the "master" (expected behavior/design) and the "shadow" (actual data/behavior) allows for continuous deviation analysis. This helps identify opportunities to improve designs and processes of the next generation, creating a cycle of continuous improvement that goes beyond monitoring current operations.

Varieties of digital twins in manufacturing

Digital twins can be classified based on what they virtualize:

- Product twins: These are digital representations of real, individual products. They capture data throughout the product lifecycle, providing insights into product behavior and optimization potential. They can be used to share data across organizations or to plan, monitor, and optimize products at all stages of their lifecycle, including their environmental footprint and energy efficiency.

- Machine, system, and technology twins: These twins represent the real-time status of equipment or installations during production. They allow for automatic recording and control of system energy efficiency or early identification of maintenance requirements (predictive maintenance for manufacturing).

- Process twins: Digital process twins link technical factory processes with enterprise-level business processes. This allows for viewing systems as a whole and gaining meaningful insights, such as production planning and business model development, based on a solid data foundation.

Many talk about digital twins, but the critical takeaway here is their synergy with IoT and AI. A digital twin without real-time data from IoT is just a static model. And without AI to analyze that data and optimization techniques, the twin can't truly predict or optimize. This powerful combination transforms a digital replica into an intelligent, self-optimizing system, leading to truly smart manufacturing. - Vitali Usau, Head of Innovation and Mobile, Emerline

Revolutionary Benefits of Digital Twins in Manufacturing

Increased operational efficiency and productivity

Digital twins provide a comprehensive view of operations, helping to identify bottlenecks, inefficiencies, and opportunities for process improvement. Manufacturers can optimize production flows by simulating various scenarios without disrupting actual operations. A McKinsey report indicates that digital twin-enabled process optimization can increase overall production efficiency by 10-15%. Companies implementing digital twins report productivity gains of 30-60%.

Cost reduction and resource optimization

Digital twins generate cost savings through multiple avenues: reduced downtime, optimized maintenance, improved quality, and enhanced operational efficiency. They also reduce costs associated with physical prototyping by enabling virtual testing. Capgemini research shows that manufacturers implementing digital twins have achieved 10-15% cost reductions in product development and 15-25% in operational costs. Siemens, using digital twins, has reduced operational costs by up to 30%.

Predictive maintenance and downtime reduction

Digital twins enable the identification of potential failures before they occur by continuously monitoring equipment conditions and performance patterns. A GE Digital study found that digital twin technology reduced unplanned downtime by up to 45% in industrial settings. A Deloitte study revealed that predictive maintenance increases equipment uptime by 10-20% and reduces maintenance costs by 5-10%.

Enhanced product quality

Real-time monitoring of production processes and comparison against ideal parameters helps identify quality issues at their source. This allows manufacturers to make immediate adjustments to maintain product quality. Siemens reported a 50% reduction in defect rates after implementing digital twin technology in some manufacturing facilities.

Contribution to sustainable development

Digital twins can optimize energy and resource consumption, contributing to more sustainable manufacturing practices and reducing environmental impact. The International Energy Agency (IEA) estimates that digital twin technology could help reduce industrial energy consumption by up to 10%.

These benefits of digital twins are interconnected and mutually reinforcing, creating a cumulative effect. For example, predictive maintenance directly reduces downtime, enhancing operational efficiency and productivity. This comprehensive approach forms a "virtuous cycle" of improvements, where each enhancement contributes to further positive changes. The ability to optimize processes for sustainable development positions digital twins not only as a tool for increasing profits but also as a strategic asset for fulfilling corporate social responsibility and complying with growing environmental regulations. This extends their strategic value beyond immediate financial returns, supporting compliance with growing global demands.

Below is a table summarizing the key quantitative benefits of digital twins in manufacturing, allowing for a quick assessment of their potential impact and justification for investment in this technology.

| Benefit | Quantitative Impact | Source |

| Reduced unplanned downtime | Up to 45% | GE Digital |

| Increased productivity | 10-15% (overall efficiency); 30-60% (productivity) | McKinsey; Simio |

| Reduced operational costs | 15-25% | Capgemini |

| Reduced product development costs | 10-15% | Capgemini |

| Reduced defects | 50% | Siemens |

| Increased equipment uptime | 10-20% | Deloitte |

| Reduced maintenance costs | 5-10% | Deloitte |

| Reduced industrial energy consumption | Up to 10% | IEA |

Key Use Cases of Digital Twins

Digital twins are widely applied across various aspects of the manufacturing lifecycle, from initial design to operation and maintenance.

Product design and development

Digital twins serve as a virtual "sandbox" for product development, allowing engineers and designers to test and iterate their ideas in a virtual environment. This capability significantly reduces the time and cost associated with physical prototyping, enabling a more agile and experimental approach to design.

Industry examples:

- Boeing uses digital twins to design, test, and maintain aircraft, leading to an 80% reduction in assembly time and a 50% reduction in software development time.

- Every Tesla car has a digital twin that collects data throughout its lifecycle, helping to improve design and predict maintenance needs.

- BMW simulates vehicle performance under various conditions and tests new features, accelerating the development cycle.

Airbus reduced rework by 20% by simulating all aspects of aircraft performance.

Manufacturing process and schedule optimization

Digital twins enable the creation of virtual models of manufacturing processes, equipment, and systems for monitoring and optimization. By simulating various scenarios, manufacturers can optimize production flows, identify bottlenecks, and inefficiencies, and adapt to changes in demand.

Industry examples:

- Siemens at its Amberg plant uses a virtual replica of the entire production process, resulting in a 30% increase in the ability to adjust production volumes, a 20% boost in productivity, and a 40% enhancement in space efficiency.

- Unilever uses digital twins to optimize production lines, reduce waste and energy consumption, and ensure quality consistency across different production sites.

Predicting equipment failures and proactive maintenance

Digital twins can predict when components are likely to fail and schedule maintenance proactively to avoid unexpected breakdowns. By analyzing real-time data, they enable the identification of anomalies and corrective actions before problems arise.

Industry Examples:

- General Electric uses digital twins to monitor and maintain its fleet of jet engines, resulting in a 40% reduction in reactive maintenance and increased engine uptime.

- Caterpillar monitors heavy machinery performance in real-time, predicting maintenance needs and avoiding unexpected breakdowns.

Virtual testing and scenario simulation

Digital twins can run various "what-if" scenarios to predict asset behavior under different conditions. This significantly reduces the risks associated with costly physical prototypes and rework, enabling faster and more economical experimentation.

The wide range of use cases demonstrates the versatility and applicability of digital twins throughout the entire product and manufacturing lifecycle. This signals a shift from siloed optimizations to a holistic, integrated approach to manufacturing management, encompassing all stages from design to operation. The ability to test and iterate ideas in a virtual environment and to experiment with design changes while reducing the risk of costly errors highlights how digital twins democratize innovation. They lower entry barriers and the cost of experimentation, allowing companies to be bolder in their ideas and accelerate development cycles.

Below is a table illustrating specific examples of digital twin applications across various industries, demonstrating their practical value.

| Use case scenario | Specific application | Company/Industry | Key outcome/benefit |

| Product design and development | Aircraft design and testing | Boeing | 80% reduction in assembly time, 50% reduction in software development time |

| Product design and development | Vehicle design improvement and maintenance prediction | Tesla | Improved design, prediction of maintenance needs |

| Product design and development | Vehicle performance simulation and new feature testing | BMW | Accelerated development cycle, enhanced safety |

| Product design and development | Reduced rework in aircraft manufacturing | Airbus | 20% reduction in rework |

| Manufacturing process optimization | Optimization of entire production line | Siemens (Amberg plant) | 30% increase in volume adjustability, 20% productivity boost, 40% space efficiency |

| Manufacturing process optimization | Optimization of production lines, waste reduction | Unilever | Reduced waste and energy consumption, improved OEE |

| Predictive maintenance | Monitoring and maintenance of jet engines | General Electric (GE) | 40% reduction in reactive maintenance, increased engine uptime |

| Predictive maintenance | Monitoring and maintenance prediction for heavy machinery | Caterpillar | Increased equipment uptime, reduced maintenance costs |

Integration with IoT and Artificial Intelligence: Combo for Smart Manufacturing

The true power of digital twins is realized through their deep integration with the Internet of Things and Artificial Intelligence. This combination creates a dynamic system capable of real-time data collection, intelligent analysis, and informed decision-making.

How IoT provides real-time data

IoT devices and sensors are deployed throughout the manufacturing environment to collect real-time temperature, pressure, vibration, machine performance, and product quality data. These sensors serve as the "eyes and ears" of the physical world, continuously transmitting information. The collected data is then transmitted to a central system, often cloud-based, for processing and analysis, forming the foundation for the digital twin.

The role of AI and Machine Learning in data analysis and decision-making

Once vast amounts of data are collected by IoT devices, AI and machine learning algorithms come into play. AI acts as the system’s "brain," analyzing this data to identify patterns, detect anomalies, and generate predictive insights. For example, based on historical data and real-time sensor inputs, AI can predict when a machine is likely to fail. This enables automated decision-making to optimize manufacturing processes.

This integration of IoT and AI transforms digital twins from mere models into intelligent, self-optimizing systems. IoT acts as the raw data provider, while AI processes and interprets this data to derive actionable insights and automate decisions. Such an integration is key to proactive, rather than reactive, manufacturing management.

The feedback mechanism between the physical and virtual worlds

The continuous flow of data from IoT devices, combined with AI analysis, enables real-time monitoring of the physical object. Digital twins represent a dynamic bridge between the physical and digital worlds via a real-time, bidirectional connection, ensuring continuous data synchronization. The insights gained from the digital twin are used to optimize physical operations, creating a continuous improvement cycle. This continuous, intelligent feedback loop is critical for realizing the stated benefits, such as predictive maintenance and operational efficiency. Without this constant synchronization and data analysis, the "twin" would quickly become outdated and lose its predictive value, highlighting the need for robust data infrastructure and continuous updates.

Digital Twin Market: Projected Growth and Outlook

The digital twin market in manufacturing is demonstrating impressive growth rates, confirming its strategic importance for the industry’s future.

Current market size and growth forecasts

The global digital twins in the manufacturing market were valued at approximately USD 10.27 billion in 2023. It is projected to grow to around USD 714.01 billion by 2032, exhibiting a compound annual growth rate (CAGR) of roughly 60.20% between 2024 and 2032. Other forecasts also indicate significant growth: USD 155.84 billion by 2030 with a CAGR of 34.2%, and USD 125.7 billion by 2030 with a CAGR of 39.48%. Forbes reports that the digital twin market is expected to reach USD 110 billion by 2028, growing annually by 61.3% from 2023 to 2028.

The significant difference in market growth forecasts among various sources (CAGR from 34.2% to 60.20%) indicates a rapidly evolving and relatively new market where forecasting methodologies may vary. However, the consensus clearly points to strong growth, suggesting high confidence in the future of the technology and its potential for widespread adoption.

Key growth drivers

The growth of the digital twin market is driven by several key factors:

- Growing focus on predictive maintenance: The increasing importance of predictive maintenance across production facilities is a significant driver, as digital twins play a crucial role in this strategy. They create accurate digital copies of physical assets that can be continuously monitored, helping predict when machine parts require maintenance or replacement. This reduces downtime and prevents significant business losses.

- Growing demand in the medical industry: Increasing demand for digital twins in manufacturing medical equipment, accessories, and medicines, driven by the need to ensure superior product quality and avoid defects in the manufacturing process.

- Increasing use in the automotive industry: The rise of electric vehicles (EVs) and the need for new engineering solutions fuel the adoption of digital twin systems in producing and designing new vehicles, including their use in the production of luxury cars and sports cars.

- Integration of Machine Learning and Artificial Intelligence: The continuous evolution of digital twin technology, especially the integration of advanced systems like AI and ML, improves the final output of digital twin solutions. These technologies, along with big data and real-time data integration, enhance the final production of digital twin solutions.

- Need for cost-effective operations and reduced time-to-market: Manufacturers strive to optimize processes and accelerate product launch in a highly competitive environment, making digital twins an indispensable tool.

The growth drivers highlight that market development is not merely driven by organic evolution but by specific industry needs and technological advancements. This means that companies adopting digital twins respond to clear operational challenges and leverage synergistic technologies to gain competitive advantages.

Below is a table illustrating various growth forecasts for the digital twin market in manufacturing, emphasizing the overall trend towards significant expansion.

| Forecast Source | Market Size (2023/2024) | Projected Market Size (by 2030/2032) | CAGR (Period) |

| Grand View Research | ~24.97 billion USD (2024) | ~155.84 billion USD (2030) | ~34.2% (2025-2030) |

| Simio | Not specified | ~125.7 billion USD (2030) | ~39.48% |

| Forbes (via Simio) | Not specified | ~110 billion USD (2028) | ~61.3% (2023-2028) |

Digital Twins: Changing the Risk Profile of Innovation

Digital twins fundamentally change the risk profile of innovation and optimization in manufacturing. They eliminate the need for costly physical prototypes and rework, allowing for virtual testing and simulation.

This technology enables faster, more economical experimentation by allowing companies to experiment with radical ideas virtually, identify flaws, and optimize designs without significant material or production costs. Digital twins allow designers to test and iterate their ideas in a virtual environment, significantly reducing the time and cost associated with physical prototyping and enabling a more agile and experimental approach to design. They allow for experimenting with design changes in a virtual environment before applying them to the physical asset, reducing the risk of costly errors.

By enabling virtual testing and simulation, digital twins transform innovation from a capital-intensive, physical, and high-risk endeavor into a digital, data-driven, low-risk process. This accelerates the innovation cycle and encourages bolder and more radical experimentation, as the cost and consequences of potential errors are significantly reduced.

This reduction in innovation risks fosters a culture of continuous improvement and rapid iteration, critical for maintaining competitiveness in fast-changing markets. Companies can "fail” fast, learn from their failures, and adapt without significant financial losses. The ability to identify flaws and optimize designs without significant material or production costs makes the development process more flexible and adaptable, ultimately leading to faster market introduction of innovative products.

Conclusion

Digital twins are not merely a technological trend but a fundamental shift in the manufacturing paradigm, providing unprecedented control, optimization, and innovation. Their benefits are multifaceted and interconnected, ranging from reducing downtime and costs to significantly increasing productivity and quality and contributing to sustainable development. Integrating IoT and AI transforms them into intelligent, self-optimizing systems capable of proactive decision-making.

Given the projected explosive market growth, digital twins will become an integral part of the industrial landscape, enabling companies to respond to challenges and actively shape their future. They pave the way for manufacturing where innovation is not limited by physical barriers, and optimization is a continuous, dynamic process. The development of custom digital twins is positioned as a tool for rapid, low-risk innovation, allowing companies to experiment more boldly and achieve breakthrough results.

For businesses ready to embrace this transformative power, specialized expertise in Digital twin development, such as that offered by Emerline, becomes invaluable. Leveraging deep knowledge in IoT, AI, and cloud technologies, providers like Emerline empower companies to seamlessly design, build, and implement bespoke digital twin solutions. This strategic partnership allows businesses to gain real-time insights, predict issues, optimize performance, and drive continuous innovation, ensuring a smooth transition into the digital future.

Ultimately, digital twins are not just an optional upgrade but a strategic imperative for companies striving for long-term competitiveness and sustainability in the era of Industry 4.0. Failing to adopt them means risking falling behind more adaptive and efficient competitors. The future of manufacturing will be characterized by continuous digital transformation, where digital twins will be a central element, ensuring flexibility, adaptability, and the ability to respond quickly to changing market conditions and technological innovations. This will enable the creation of truly "smart" and "agile" factories of the future.

Published on Aug 2, 2025