Table of contents

- What Is RPA in Manufacturing and Why It Matters

- A Simple Framework: The 4D RPA Layer

- Benefits of RPA in Manufacturing

- Cost efficiency at scale

- Faster processes and reduced lead times

- Higher accuracy and fewer production-affecting errors

- Optimized workforce allocation

- Consistency and full traceability

- Better use of existing systems

- RPA Use Cases in Modern Manufacturing

- Procurement and supplier operations

- Inventory control and warehouse coordination

- Production data collection and reporting

- Quality management activities

- Maintenance workflows

- Logistics and shipment tracking

- Compliance and certification support

- Master data and BOM management

- Real-Life Examples

- Automotive and Tier-1 Supplier Operations

- Electronics manufacturing

- Food and beverage manufacturing

- Heavy machinery and capital-equipment manufacturing

- Supply chain and logistics operations

- AI and RPA in Manufacturing as a Smarter Layer of Automation

- What this looks like on the factory floor

- Three levels of intelligent automation

- Level 1: RPA alone

- Level 2: RPA with AI assistance

- Level 3: Full intelligent automation

- Why this matters

- RPA and Industry 4.0: The Automation Layer That Connects It All

- Why RPA matters in the Industry 4.0 landscape

- RPA strengthens the core principles of Industry 4.0

- Connectivity

- Transparency

- Adaptability

- Autonomy

- A practical example

- Where manufacturers often begin

- The long-term impact

- Digital Twins and RPA: How To Close the Loop Between Insight and Action

- How digital twins use RPA

- A simple workflow example

- Why this connection matters

- Where manufacturers usually start

- Looking at the bigger picture

- Common Challenges and How to Overcome Them

- Process readiness

- Data quality and system hygiene

- Choosing the wrong first process

- Limited cross-functional alignment

- Underestimating maintenance

- Change management barriers

- Cybersecurity and access control

- A Practical Roadmap for RPA Adoption in Manufacturing

- Step 1. Discover and prioritise

- Step 2. Build a focused pilot

- Step 3. Establish standards and governance

- Step 4. Scale across the operation

- Step 5. Introduce AI and intelligent capabilities

- Step 6. Move toward continuous improvement

- Conclusion: RPA Is Quietly Becoming a Foundation of the Modern Factory

Manufacturing today is more about agility, connectivity, data, and speed than it is about machines and lines. With global supply chains under strain, customer demands rising, and labour shortages becoming persistent, one thing is clear: the factories that win in the next decade will be digitally responsive.

What are the most powerful levers in that transformation? We would like to mention Robotic Process Automation, which involves software bots that handle processes, connections, and decisions behind the scenes. RPA doesn't automate physical tasks; instead, it automates information flows, decision points, and exceptions — tasks that often slip through the cracks of traditional automation.

What Is RPA in Manufacturing and Why It Matters

RPA uses software bots to automate tasks that follow predefined rules and consistently repeat the same steps. These bots simulate human interactions with digital systems. They open applications, enter information, extract data, update databases, and trigger workflows in the same way an employee would.

Unlike physical automation, RPA focuses on information flows rather than material flows.

In a manufacturing environment, these bots can log into ERP systems, update inventory records, generate production reports, pull machine data, create purchase orders, reconcile invoices, or move information between legacy systems.

RPA is especially useful because most factories run a mix of old and new technologies. That creates countless manual handoffs. Bots eliminate those handoffs and provide teams with cleaner, more accurate data without altering the underlying IT landscape.

Here’s a framework that shows RPA not just as a cost-saver, but also as a tool for connectivity and decision enablement.

A Simple Framework: The 4D RPA Layer

| Layer | Role | Example |

| Discover | Identify tasks ripe for automation | Shifts in non-value administrative time |

| Digitize | Use bots to replace human-executed digital tasks | Bot logs into ERP to update inventory |

| Data-Connect | Integrate across systems, share data in real time | Bot moves machine output into MES & ERP |

| Drive Decisions | Trigger action or escalate exceptions | Bot triggers maintenance when machine data drops below threshold |

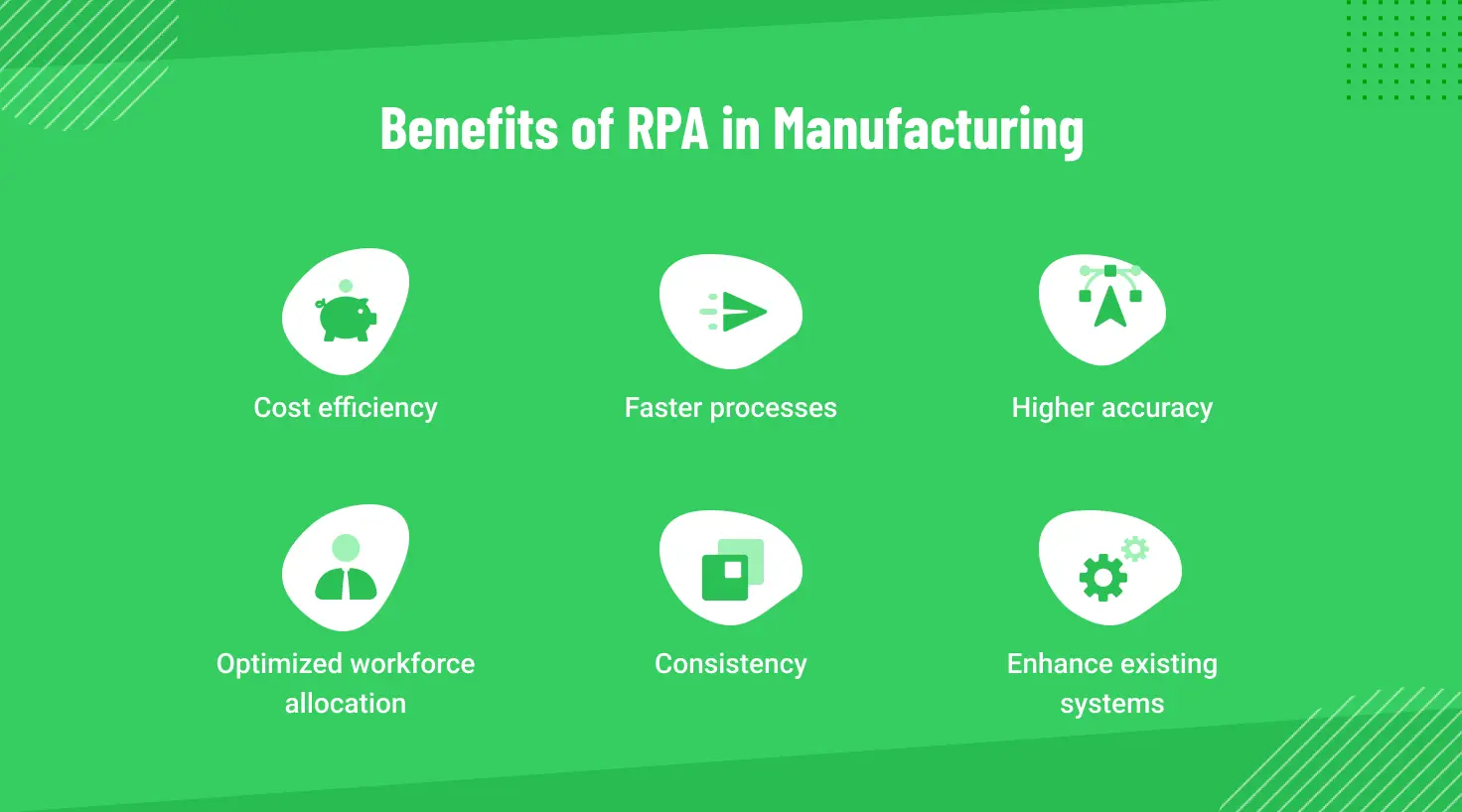

Benefits of RPA in Manufacturing

RPA delivers a set of advantages that matter to both the boardroom and the shop floor.

Cost efficiency at scale

Many manufacturing tasks appear small when viewed individually. A few minutes of data entry here, a quick reconciliation there. Multiply that by hundreds of processes and thousands of transactions, and the total cost becomes enormous. RPA reduces this cost by automating entire categories of digital work.

Faster processes and reduced lead times

Bots operate continuously and complete tasks in seconds, rather than minutes, directly impacting operational speed, communication cycles, inventory movement, and customer responsiveness.

Higher accuracy and fewer production-affecting errors

Manufacturers operate in a world where even a single incorrect quantity, batch number, or parameter can trigger delays, rework, or compliance issues. RPA eliminates routine errors and stabilizes process quality.

Optimized workforce allocation

Instead of spending hours on form entries, reconciliations, or system updates, employees can shift their focus to root cause analysis, equipment optimization, supplier communication, or innovation projects, which is critical in industries where skilled talent is becoming increasingly scarce.

Consistency and full traceability

Bots follow the same rules every time, creating consistent digital footprints, simplifying audits, and strengthening compliance with industry standards.

Better use of existing systems

Rather than forcing expensive system replacements, RPA extends the life and usefulness of ERP, MES, LIMS, and other legacy solutions by connecting them in ways they were never designed for.

RPA Use Cases in Modern Manufacturing

Manufacturers are applying RPA across the entire value chain. Here are the most impactful areas.

Procurement and supplier operations

RPA handles tasks such as reading supplier emails, extracting order confirmations, updating delivery dates, verifying invoice accuracy, reconciling discrepancies, and preparing vendor scorecards, all of which help speed up supply chain cycles and reduce downstream disruptions.

Inventory control and warehouse coordination

Bots can monitor stock levels, match receipts with purchase orders, synchronize counts across systems, prepare replenishment triggers, and identify anomalies more quickly than any manual process.

Production data collection and reporting

Production teams often spend hours gathering figures scattered across multiple systems, including MES, spreadsheets, machine logs, and quality systems. RPA consolidates this data automatically and generates reports at the frequency required by management.

Quality management activities

Bots can pull inspection results, structure them, flag issues, route deviations for review, update quality logs, and maintain documentation accuracy throughout the product lifecycle.

Maintenance workflows

Condition monitoring tools or simple machine signals can feed information to RPA bots. The bots then create work orders, notify technicians, update schedules, and ensure correct documentation.

Logistics and shipment tracking

RPA retrieves carrier updates, adjusts expected delivery times, updates customer systems, and alerts supply chain managers when delays threaten production schedules.

Compliance and certification support

From document version control to batch record verification, RPA strengthens regulatory alignment and ensures tasks are completed exactly as required.

Master data and BOM management

Bots maintain consistency in bills of materials, product attributes, part numbers, and configuration rules across multiple systems, reducing product errors and engineering rework.

Real-Life Examples

Manufacturing operations vary dramatically across industries, but every plant contains repetitive digital tasks, system gaps, and cross-functional workflows that drain time and create friction. RPA helps close those gaps by automating the digital handoffs that humans currently manage manually.

Automotive and Tier-1 Supplier Operations

Automotive supply chains generate massive volumes of invoices, delivery notes, ASN updates, shipment confirmations, and quality documents. A leading Tier-1 supplier deployed RPA to automate invoice capture, validation, and ERP reconciliation across multiple plants.

What RPA did:

- Captured data from vendor invoices using bots

- Validated line items against POs automatically

- Flagged mismatches for exception handling

- Updated ERP systems at high frequency

- Streamlined communication with suppliers

The impact:

- 82% reduction in invoice-processing time

- Dramatically fewer supplier disputes

- Faster month-end close and improved cash-flow visibility

- A more resilient procurement back office during peak production cycles

This case illustrates how RPA meets the automotive sector’s demand for speed, accuracy, and high-volume transaction consistency, particularly as order changes and supply constraints persist, posing challenges for global OEMs.

Electronics manufacturing

Electronics production often involves high-mix, low-volume changes, frequent BOM revisions, and complex component inventories. A major electronics manufacturer introduced RPA to maintain BOM accuracy and streamline inventory updates across disconnected systems.

What RPA did:

- Automated BOM versioning across PLM and ERP

- Synced part-number attributes in real time

- Eliminated manual spreadsheet updates

- Ensured engineering changes propagated correctly across departments

The impact:

- 40% reduction in operational costs

- Faster engineering-to-production transition

- Reduced rework due to BOM discrepancies

- Improved production scheduling accuracy

This case illustrates how RPA helps stabilize the informational backbone that electronics manufacturers rely on to keep cycle times short and yields high.

Food and beverage manufacturing

Food processing environments operate with strict compliance requirements, and documentation must be consistent, accurate, and submitted on time. A global confectionery and packaged-goods company used RPA to automate accounts payable across 31 manufacturing facilities.

What RPA did:

- Automated invoice ingestion and validation

- Processed large volumes of supplier documents with minimal human touch

- Standardised AP workflows across plants

- Reduced errors caused by paper-based or email submissions

The impact:

- 75% reduction in manual effort for key AP processes

- Faster payments to critical raw-material suppliers

- Unified reporting across all plants

- A more stable cost structure for core operational expenses

This powerful example illustrates how RPA enhances compliance, documentation, and financial controls, which are key concerns in regulated food environments.

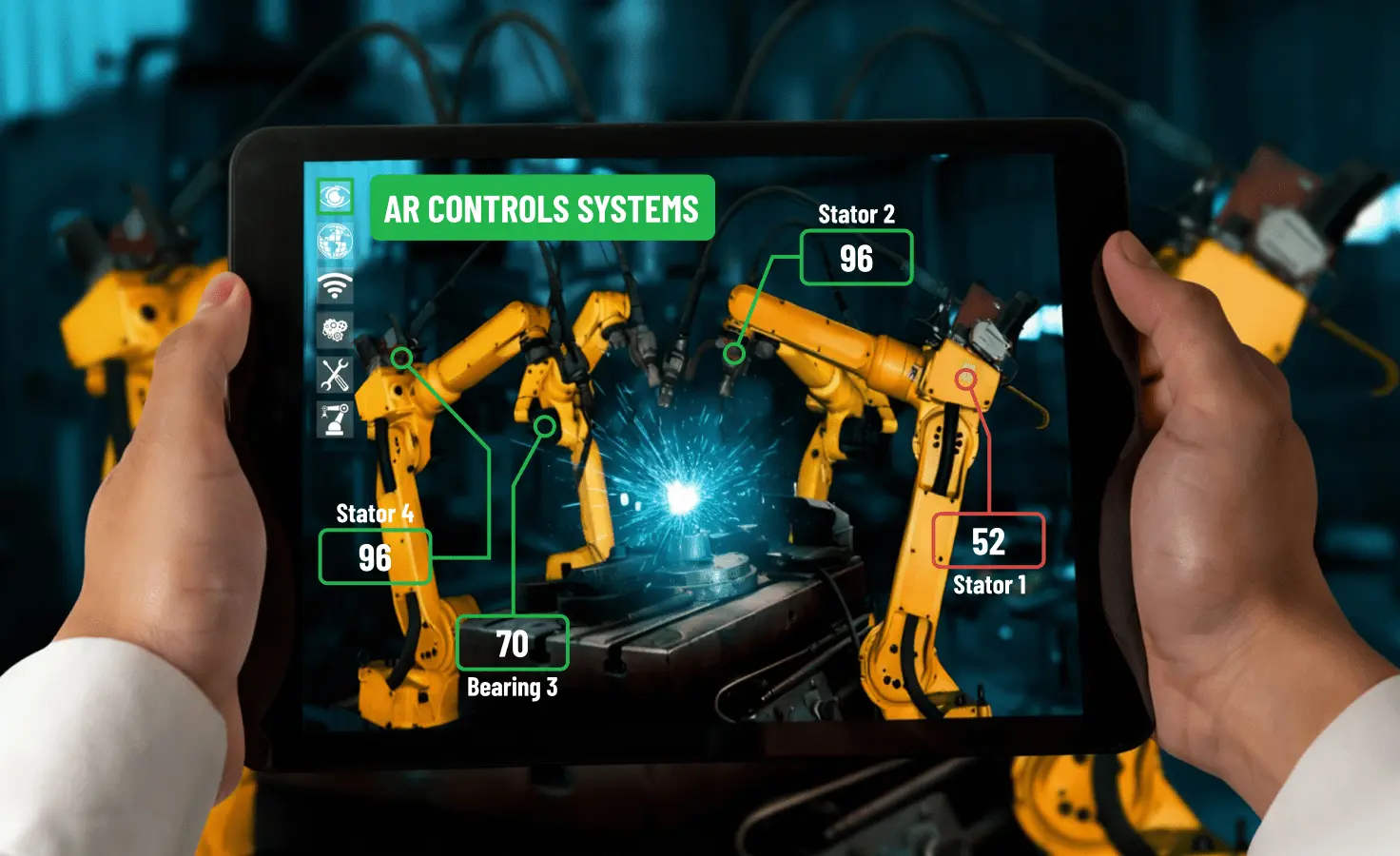

Heavy machinery and capital-equipment manufacturing

Manufacturers of high-value equipment face unique costs associated with downtime. One heavy-equipment plant integrated RPA into a larger predictive-maintenance and digital-twin solution that simulated machine behaviour and triggered maintenance actions automatically.

What RPA did:

- Collected sensor readings and equipment logs

- Updated the digital twin model continuously

- Triggered work orders when early faults appeared

- Updated MES and maintenance planning systems

- Maintained equipment history records automatically

The impact:

- Around 40% reduction in downtime

- 30% improvement in defect rate

This case shows how RPA becomes deeply valuable when connected to IoT and integrated into virtual factory environments, allowing teams to resolve issues before they escalate.

Supply chain and logistics operations

Supply chain volatility is one of the biggest risks manufacturers face today. RPA helps provide real-time visibility and consistency when dealing with delivery delays, unstable supplier performance, and fluctuating raw-material availability.

A study on digital twin-enabled automation showed significant operational improvements when combining RPA, real-time data, and simulation models.

What RPA did:

- Pulled live shipment data from carrier portals

- Updated internal ETA forecasts

- Triggered alerts when delivery risk increased

- Assisted digital twin systems in evaluating contingency scenarios

- Automated communication with key stakeholders across procurement and planning

The impact:

- Around 85% reduction in unexpected downtime for a production line using integrated twin-automation

This example demonstrates how custom RPA solutions can support end-to-end supply chain resilience by mitigating uncertainty and making proactive adjustments before production is impacted.

AI and RPA in Manufacturing as a Smarter Layer of Automation

RPA is excellent at handling structured, repetitive tasks. It follows rules, completes steps the same way every time, and works reliably across different systems. But manufacturing data is rarely clean or uniform. Sensor readings, operator notes, machine logs, and supplier emails often fall outside strict rules, providing artificial intelligence with an opportunity to complement RPA and elevate it into intelligent automation.

At a basic level, AI interprets information, and RPA executes actions. AI figures out what needs attention. RPA executes the steps that convert insights into results.

Together, they automate work that once required human judgment.

What this looks like on the factory floor

- AI can analyse inspection images, identify defects, and classify patterns. RPA can instantly log the issue, update quality records, and trigger corrective steps.

- AI models can predict equipment wear. RPA can create a maintenance order, book a spare part, and notify technicians.

- AI can read supplier messages or unstructured documents. RPA can take the interpreted information and update manufacturing ERP or MES systems with consistent accuracy.

In each case, AI removes ambiguity, and RPA removes delay.

Three levels of intelligent automation

Most manufacturers move through three stages as they mature:

Level 1: RPA alone

Bots handle structured, rule-based tasks: reporting, data entry, invoice validation, and system updates, helping to deliver fast ROI and reduce errors.

Level 2: RPA with AI assistance

AI helps with documents, emails, images, or sensor readings. Bots can now manage exceptions and unstructured inputs, expanding automation into areas that previously required human review.

Level 3: Full intelligent automation

AI predicts issues or opportunities. RPA acts immediately. Digital twins and data platforms close the loop, continuously refining the process. At this level, the manufacturers see the most significant gains in responsiveness and efficiency.

Why this matters

Pairing AI with RPA shortens decision cycles. Tasks, such as reviewing logs, validating data, and escalating issues, that once took hours can now be completed in seconds. Processes become more stable, less dependent on manual monitoring, and significantly more adaptive to real-world conditions.

The combination does not replace people. It provides them with cleaner information, fewer routine decisions, and more time to focus on improvement and innovation.

RPA and Industry 4.0: The Automation Layer That Connects It All

Industry 4.0 is often described as the next wave of manufacturing, characterized by the integration of connected machines, real-time data, and highly automated, self-adjusting operations. But for many manufacturers, the challenge is connecting today’s reality of mixed systems, legacy platforms, and manual workflows with the promise of a smart factory.

This is where RPA plays a practical, often underestimated role.

Why RPA matters in the Industry 4.0 landscape

Industry 4.0 relies on data flowing smoothly across machines, departments, and digital platforms. In real factories, that flow is often blocked by outdated interfaces, manual handoffs, and system gaps. RPA bridges these gaps without waiting for expensive system replacements.

Bots can transfer information between ERP, MES, PLM, scheduling systems, and shop-floor devices, ensuring data alignment even when systems cannot communicate directly with each other. That makes Industry 4.0 initiatives faster to implement and far easier to scale.

RPA strengthens the core principles of Industry 4.0

Connectivity

RPA links systems that were never built to integrate. It ensures data captured at the machine level reaches the right platforms, including planning, quality, or analytics.

Transparency

Industry 4.0 depends on real-time visibility. RPA updates dashboards, consolidates reports, and feeds analytics engines with clean, up-to-date information.

Adaptability

When conditions change, RPA enables the factory to respond more quickly. It can adjust schedules, update material requirements, trigger maintenance tasks, or re-route workflows based on changing conditions.

Autonomy

As AI, IoT, and digital twins generate insights, RPA converts those insights into actionable steps. Over time, this creates a system that actively manages itself rather than waiting for manual intervention.

A practical example

Imagine a production line equipped with sensors feeding real-time performance data to an analytics engine. The engine predicts a throughput drop in the next shift. Without RPA, someone must notice the alert, adjust the plan, notify the team, and update scheduling software.

With RPA, the system reacts automatically:

- The schedule is updated

- A supervisor is notified

- Material flow is adjusted

- The digital twin logs the change

Industry 4.0 becomes a reality that is lived every day.

Where manufacturers often begin

Most companies begin by digitizing areas where manual work slows the flow of information, such as reporting, inventory reconciliation, quality updates, or maintenance logs. These early wins lay the foundation for later steps, such as IoT integration, predictive analytics, and digital twins.

RPA makes each of those steps easier by reducing friction in the surrounding processes. It ensures that Industry 4.0 projects deliver measurable value rather than becoming isolated pilots.

The long-term impact

As more processes become connected and more decisions are driven by automated logic, manufacturers gain a factory that is not only efficient but also continuously improving.

Industry 4.0 is not just about smart equipment. It is about how information moves, how decisions are made, and how quickly a factory can adapt.

RPA helps build that environment by filling the operational gaps that slow transformation, ensuring that the benefits of Industry 4.0 can be realised sooner, and with far less disruption.

Digital Twins and RPA: How To Close the Loop Between Insight and Action

As mentioned earlier, digital twins are becoming a core part of the modern manufacturing industry. They provide you with a virtual version of a machine, a line, or even an entire factory. This model operates on real operational data, enabling teams to test scenarios, predict outcomes, and identify problems before they disrupt production.

However, even the most sophisticated digital twin requires two key elements to deliver value: a steady stream of accurate data and a reliable method for acting on insights generated. At this point, RPA becomes the missing link.

How digital twins use RPA

RPA helps digital twins stay synchronized with the real world. Bots can collect data from machines, sensors, and legacy systems, then feed it into the twin automatically, helping to remove manual data handling, which is often slow and inconsistent.

On the output side, when the digital twin detects an anomaly or suggests an improvement, RPA executes the corresponding operational steps. A bot can adjust a production schedule, initiate a maintenance order, or update a planning system immediately, without waiting for human intervention, creating a direct link between simulation and real operations.

A simple workflow example

- Machine data flows into the digital twin.

- The twin simulates performance and spots an early deviation.

- It recommends a maintenance action.

- RPA triggers the work order, books the technician, and logs the update in ERP or MES.

No delays, no missed alerts, no manual copying of data between systems.

Why this connection matters

Digital twins offer valuable insights, but insight alone does not solve problems. By pairing the twin with RPA, manufacturers achieve a closed-loop system where issues are detected early and prompt actions are taken.

This leads to:

- Fewer unexpected stoppages

- More accurate schedules

- Better use of technician time

- Stronger equipment reliability

- Higher predictability across the line

Where manufacturers usually start

Most organisations first build a digital twin around a single machine or critical asset. Then they introduce RPA to automate data collection and routine responses. As confidence grows, they expand the twin to cover entire lines or plants and use RPA to drive more complex actions.

This step-by-step approach keeps risk low while steadily increasing automation maturity.

Looking at the bigger picture

When digital twins, AI, and RPA work together, manufacturers gain a factory that can see, understand, and respond, often before people realize something needs attention.

It is one of the most practical paths toward a more autonomous, self-optimizing operation.

Common Challenges and How to Overcome Them

Even with strong business cases, RPA projects in manufacturing can stumble if the fundamentals aren’t in place. Most challenges are not technical; they come from processes, data, and cross-functional alignment. The good news is that each one can be managed with the proper preparation.

Process readiness

RPA works best on stable, rule-based processes. In many factories, however, workflows vary by shift, team, or plant. When the process keeps changing, bots struggle to keep up.

How to address it:

Standardise the workflow first. Even light harmonisation, defining one “best way” across multiple teams, dramatically increases RPA success and reduces maintenance overhead.

Data quality and system hygiene

Bots depend on the data they receive. Inconsistent naming, manual workarounds, or outdated master data can cause unexpected exceptions.

How to address it:

Before deployment, review data inputs to ensure they are accurate and consistent. A small cleanup effort up front can prevent dozens of recurring issues later on.

Choosing the wrong first process

Selecting a low-volume or highly variable process can make automation look less effective than it truly is.

How to address it:

Start with high-volume, transactional tasks where rules are clear, and the payoff is visible. Early wins build momentum and credibility for scaling.

Limited cross-functional alignment

Manufacturing processes often span operations, engineering, IT, procurement, and finance. If one group is not on board, the progress of automation slows.

How to address it:

Create a cross-functional working group. Involve IT for access and security, operations for process clarity, and finance for ROI validation.

Underestimating maintenance

Bots are digital workers, and like any worker, they need oversight. System changes, interface updates, or new rules can affect performance.

How to address it:

Implement monitoring and treat bots as part of the operational environment. A small Centre of Excellence or automation owner ensures long-term stability.

Change management barriers

Some teams worry automation will replace jobs or disrupt routines. Without clear communication, even successful pilots may face resistance.

How to address it:

Explain the role of RPA early: it removes repetitive tasks, not skilled work. Highlight how it frees people to focus on engineering improvements, quality analysis, and higher-value problem-solving.

Cybersecurity and access control

Because bots interact with core systems, access rights and auditability are essential.

How to address it:

Work closely with IT to establish proper credentials, logging, and security protocols, and to ensure automation remains aligned with corporate policies and is safe to scale.

A Practical Roadmap for RPA Adoption in Manufacturing

A successful RPA program grows incrementally. It starts small, proves value quickly, and scales with confidence. Below is a practical roadmap designed explicitly for manufacturing teams seeking to leverage automation as a strategic capability.

Step 1. Discover and prioritise

Begin by mapping your digital tasks. Look for processes that are repetitive, rule-based, and executed frequently. These roles are typically found in procurement, inventory control, quality administration, or maintenance scheduling.

A simple value-versus-effort assessment helps you identify where automation will yield the most significant benefits.

Step 2. Build a focused pilot

Select one or two clearly defined processes. The goal is to deliver visible results in a short timeframe, not to automate everything at once.

Most pilots run for six to eight weeks and demonstrate immediate gains, including shorter cycle times, fewer errors, and significant hours of manual work saved.

Step 3. Establish standards and governance

Once the first wins are in place, set up the foundation for scale. This includes:

- naming conventions

- documentation practices

- testing guidelines

- monitoring rules

- security and access protocols

A small Centre of Excellence or automation lead can coordinate these elements and ensure consistency across plants.

Step 4. Scale across the operation

With governance in place, expand into new areas. Manufacturing teams commonly scale into supply chain operations, quality management, production reporting, engineering change control, and maintenance workflows.

At this stage, automation becomes an integral part of regular operational planning, rather than a side project.

Step 5. Introduce AI and intelligent capabilities

As confidence grows, start combining RPA with AI tools and digital twins. This bridges the gap between insight and execution.

Predictive models can identify issues early, and bots can trigger actions promptly, resulting in faster and more stable decision-making cycles.

Step 6. Move toward continuous improvement

The final stage is not a finish line but a mindset. Treat automation as a living system that can evolve with your processes.

Review performance regularly, evaluate new automation candidates, refine existing bots, and integrate emerging technologies as needed.

Conclusion: RPA Is Quietly Becoming a Foundation of the Modern Factory

RPA is no longer just a cost-cutting tool. It is becoming a core capability of modern manufacturing, closing the gap between systems, accelerating decisions, and enabling teams to focus on what truly matters.

When combined with AI, digital twins, and Industry 4.0 principles, RPA turns disconnected processes into a connected, intelligent, responsive production ecosystem.

Factories that adopt RPA now gain speed, reliability, and operational maturity. Factories that combine it with intelligent technologies gain a competitive advantage that compounds over time.

Published on Dec 11, 2025