Your Manual to Choosing the Right ERP System for a Manufacturing Business

Table of contents

- What an ERP System Really Does for Manufacturers

- Why ERP Selection Matters More Than Ever

- The Core ERP Selection Criteria Every Manufacturer Should Consider

- Functional capabilities: The beating heart of operations

- Supply chain and procurement: keeping the flow moving

- Finance that understands manufacturing

- Technical architecture and integration: the hidden strength

- Analytics and AI: turning data into foresight

- Usability and adoption: because people make systems work

- Vendor reputation and industry experience

- Cost and total cost of ownership

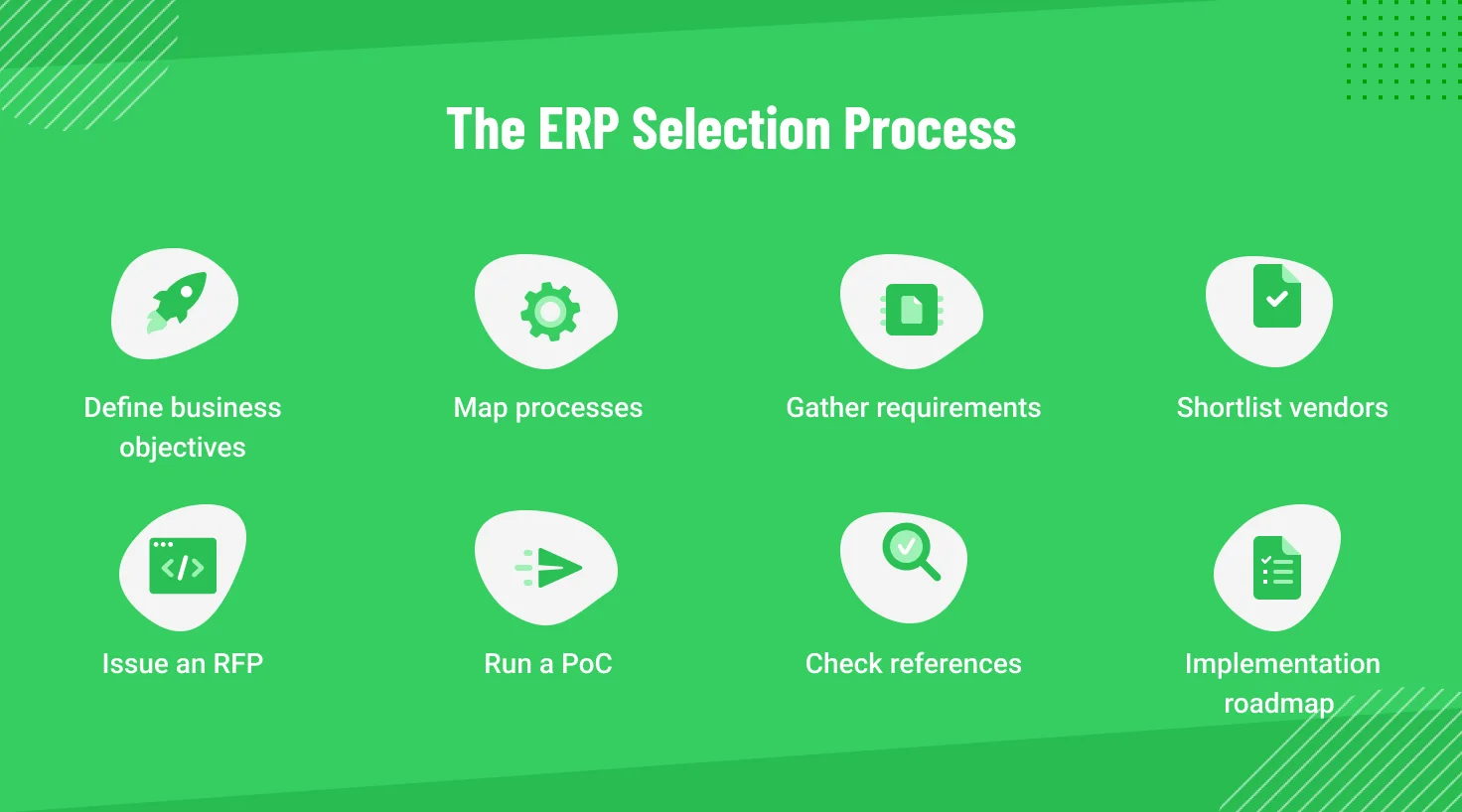

- The ERP Selection Process: How to Get It Right

- Define business objectives

- Map processes

- Gather requirements

- Shortlist vendors

- Issue an RFP

- Run a proof of concept

- Check references

- Negotiate and set up the implementation roadmap

- What Is Better to Avoid

- Falling for the brand, not the fit

- Underestimating the people factor

- Ignoring integration complexity

- Skipping proof-of-concept testing

- Treating ERP like an IT project

- The Future: AI, IoT, and the Smart Factory

- Conclusion

One of the precision parts manufacturers in Ohio wanted to improve its operations with an enterprise resource planning (ERP) system. They expected to start running the processes more efficiently. After six months of using the new system, they discovered that the production data was still not syncing properly, and the employees had to deal with good old Excel sheets.

Their mistake? Choosing an ERP that looked powerful on paper but didn’t fit their actual manufacturing workflows.

They’re not alone. According to the Rand Group, 55-75% of ERP projects fail to meet their objectives, mainly due to poor selection or inadequate change management.

For manufacturers, ERP is more than just software — it’s the digital backbone that links production, procurement, finance, and customers. A poor fit can slow growth and add cost; a well-fitting system compounds operational and financial gains.

This guide breaks down the ERP selection criteria every manufacturing company should use — blending practical evaluation steps with lessons learned from real-world implementations.

What an ERP System Really Does for Manufacturers

We spoke with many manufacturers, trying to understand their real expectations from an ERP system. Most of them confessed to wishing for software helping to connect all the elements and departments of a large factory, from production orders to customer deliveries. A system that would include the smallest details and not cause additional headaches.

ERP isn’t just software. It’s the command center of modern manufacturing.

Here’s how it works. When a metal component maker runs low on a critical material, the ERP doesn’t wait for someone to notice. With appropriate configuration and integrations, ERP can trigger purchase requisitions, evaluate vendor pricing, forecast schedule impact, and alert planners before downtime.

Manufacturing-focused ERPs such as SAP S/4HANA, Oracle NetSuite, or Microsoft Dynamics 365 go far beyond accounting. They include modules built for the shop floor:

- Bill of Materials (BOM) and routing management.

- Material requirements planning (MRP) to balance demand and supply.

- Shop floor control for tracking machine performance and labor in real time.

- Maintenance (EAM/CMMS) and Quality Management (QMS) for compliance and waste reduction.

In short, ERP systems don’t just record what happens — they help decide what happens next.

Why ERP Selection Matters More Than Ever

Manufacturing is a particular industry where downtime turns into evident financial losses, and selecting the most suitable ERP here means far more than just choosing which software to install. In the long run, for manufacturing, ERP choices directly affect throughput, lead times, and working capital.

And no, we are not trying to exaggerate. Here is an example: an ERP implemented by an aerospace supplier, unfortunately, lacked multi-site functionality. Together with the business growth and international expansion, each plant had to deal with its own software version, creating extra data silos and confusion. This supplier lost more than two years and faced significant financial losses to resolve the issue.

There is another example, though. An electronics assembler selected a NetSuite solution for its business. They managed to reduce the lead times by 25% and gained an opportunity to collect and run all the data from all the sites from a single dashboard.

Why are these cases so different? The thing is in the alignment between system capabilities and business reality.

The Core ERP Selection Criteria Every Manufacturer Should Consider

Functional capabilities: The beating heart of operations

The first question to ask: does the ERP understand how your factory actually works?

You’ll need strong features for:

- Production planning and scheduling — MRP, BOM versioning, capacity planning.

- Shop floor control — Real-time monitoring of machine utilization and operator productivity.

- Example: A manufacturer of automotive components connected IoT sensors to its ERP, resulting in an 18% reduction in downtime.

- Quality management — Inspections, traceability, and automated non-conformance reporting.

- Maintenance management — Preventive and predictive maintenance scheduling.

- Inventory and warehouse control — RFID tracking and real-time stock visibility.

Every module should communicate seamlessly with the next. Because when production, procurement, and finance share one truth, decisions become faster and smarter.

Supply chain and procurement: keeping the flow moving

Manufacturing supply chains are complex and fragile. An ERP must anticipate disruptions, not just record them.

Look for features such as:

- Supplier scorecards and vendor performance tracking.

- Automated purchase requisitions tied to demand forecasts.

- Logistics and freight integration for live shipment updates.

Example: Midwest Steel Manufacturing opted for a predictive maintenance analytics platform. As a result, they managed to reduce the unplanned downtime by 30% and save almost $850,000 in operational spending annually.

Finance that understands manufacturing

In too many factories, finance and operations live in separate worlds. ERP should bring them together.

A unified accounting system represents collected production data and financial results. It helps managers get a better understanding of the job costs, margins, and product profitability.

Budgeting and forecasting modules let CFOs run “what-if” scenarios: What happens to margins if steel prices rise 10%? What if we run one more shift? ERP consolidates operational and financial data so finance teams can run timely what-if scenarios.

Technical architecture and integration: the hidden strength

Beneath the dashboards lies the infrastructure. Choose a system that fits your IT strategy:

- Cloud ERP for agility and low maintenance.

- Hybrid models for firms with both modern plants and legacy systems.

- API openness for connecting with MES, PLM, CRM, or IoT solutions.

A scalable ERP grows with you — from one facility to twenty, from local orders to global demand.

Analytics and AI: turning data into foresight

Modern ERP systems don’t just record — they predict. With built-in AI, they turn raw data into foresight that drives smarter, faster decisions.

AI models spot early signs of machine failure, triggering maintenance tasks before downtime hits. They refine demand forecasts by analyzing seasonality, supplier reliability, and even weather trends, helping planners cut excess stock while keeping production steady.

AI makes ERP less of a ledger and more of a co-pilot, guiding daily operations with predictive intelligence.

Usability and adoption: because people make systems work

Even the smartest system fails if people won’t use it.

Look for clean interfaces, mobile access, and role-based dashboards. The machine operator on the floor should find the system as intuitive as the finance manager in the office.

During demos, let real users test it. If they struggle to navigate, your implementation will likely struggle as well.

Vendor reputation and industry experience

Building a reliable ERP system takes time. That is why, when selecting your vendor for this project, you choose a business partner for the long term. Such a selection requires a wise approach.

Opt for a vendor that knows your industry well. Pay special attention to the case studies and search for real customer reviews. Make sure that you will have all the necessary support even after the system launch.

Cost and total cost of ownership

Sticker price is just the beginning.

Factor in implementation, customization, training, maintenance, and upgrade costs. Over the next five to ten years, those often exceed the license cost.

Create a weighted TCO comparison matrix to visualize long-term value — not just short-term savings.

The ERP Selection Process: How to Get It Right

A structured process protects you from bias and chaos.

Define business objectives

Start with outcomes — not software. What do you want to improve?

Map processes

Specify the pain points and other peculiarities of your exact case in the main areas, including production, finance, and logistics.

Gather requirements

Talk to end users — they’ll tell you what actually matters.

Shortlist vendors

Focus on those with proven manufacturing experience.

Issue an RFP

Score proposals using measurable, weighted criteria.

Run a proof of concept

Let vendors show how they handle your data and workflows.

Check references

Ask what went right, what didn’t, and how support feels post-go-live.

Negotiate and set up the implementation roadmap

Specify the meaningful metrics and draw the management structure.

What Is Better to Avoid

To err is human, and, unfortunately, the famous "human factor" can sometimes lead even the most promising ERP project far from success. Below, we've collected the most frequent mistakes a manufacturer can make, together with the professional strategies to avoid them.

Falling for the brand, not the fit

It’s easy to be dazzled by big names and glossy demos. But the right ERP isn’t necessarily the most famous one — it’s the one that fits your workflows.

Take a steel manufacturer that invested in a big-name ERP to “modernize overnight.” The software impressed on paper, but couldn’t handle their custom fabrication workflows. Within months, production slowed, frustration rose, and the company went back to spreadsheets — proof that even the best-known systems can fail when they don’t fit the work.

Choose substance over prestige.

Underestimating the people factor

ERP success lives and dies with adoption. Training, change management, and communication are not “nice-to-haves” — they’re survival gear. The companies that thrive are the ones that bring operators, planners, and accountants into the process early, not after go-live.

Ignoring integration complexity

You can’t bolt an ERP onto chaos. If your MES, CRM, or PLM systems aren’t speaking the same language, your new ERP won’t be fluent either. Before you sign, map every data handoff and interface like you’re wiring a power grid.

Skipping proof-of-concept testing

A demo is a theater. A proof-of-concept is reality. Test real data, real transactions, and real edge cases before you buy. The hour you spend doing that can save you a year of regret.

Treating ERP like an IT project

ERP is not just technology — it’s a business transformation wrapped in software. When ownership sits only with IT, business users end up as spectators instead of champions. The best ERP projects have both the CIO and the COO at the table.

The Future: AI, IoT, and the Smart Factory

ERP is quickly evolving from a digital recordkeeper to the brain of the smart factory.

AI will anticipate equipment failures, while IoT sensors feed live data from machines and warehouses. ERP, together with Advanced Planning and Scheduling (APS), Manufacturing Execution System (MES), and Enterprise Asset Management (EAM) and IoT inputs, can automatically adjust schedules, inventory, and maintenance to create a self-correcting environment.

Sustainability metrics, energy use, and carbon tracking are increasingly appearing as standard ERP dashboards. The smartest manufacturers won’t just react to change; their systems will help design the next move.

Conclusion

Selecting an ERP is like choosing the central nervous system for your business. It must be reliable, flexible, and deeply aligned with how you operate.

When chosen strategically, an ERP system doesn’t just run your business — it helps you reinvent it.

So take your time. Involve your people. Demand clarity from vendors. And remember: ERP success lives where business strategy and technology meet.

Published on Oct 23, 2025