The development of an extensive sales analytics platform with a variety of modules aimed at facilitating the work of distributors and maximizing their performance.

Development of an Automation Platform for Biochemical Experiments

Emerline developed a solution to fully automate the client’s procedures of biochemical experiments.

Background

Our client is a Silicon Valley innovator with a division focused on discovering new methods for synthesizing biochemical compounds. Their key customers are pharmaceutical companies and defense-related organizations, imposing high demands on the speed, accuracy, and reproducibility of research.

Before contacting Emerline, the client conducted biochemical experiments manually, which, as their business grew, became increasingly time-consuming and costly. When they reached out to our team, they were under immense pressure: having received a government grant, they had only 12 months to launch the software and only about 20% of the original budget remaining. The situation presented significant challenges, which the Emerline team approached with a unique problem-solving perspective.

To address the urgent challenges, the client's company collaborated with our team in a two-day workshop where we jointly explored and presented a high-level architecture for the future solution.

Challenge

The client was impressed with our meticulous approach and clarity, so they entrusted us with moving the project forward.

During the initial discovery phase, the Emerline team identified the following challenges for the client to solve:

Time-consuming processes

Labor-intensive workflows

Low efficiency in route optimization

Reproducibility issues

Lack of a single database

Complexity of multi-step synthesis

Methodology & Approach

Based on the performed research, we identified the following client business goals:

- Accelerate drug discovery: Automate biochemical synthesis procedures end-to-end to reduce the time required for molecule design, experiment setup, execution, and analysis.

- Improve efficiency: Optimize the utilization of robotic hardware to maximize the number of experiments conducted simultaneously. In the past, the client could conduct only one experiment at a time.

- Enhance experiment accuracy: Minimize human error through automation and precise control of robotic platforms.

- Enable scalability: Provide a solution capable of handling increasing workloads and complex biochemical synthesis processes.

- Streamline data integration & collection: Integrate seamlessly with existing systems, such as formula design tools, mass spectrometry execution software, and project management systems, to create a unified workflow where data is automatically collected from lab equipment.

- Facilitate real-time insights: Ensure real-time processing, analysis, and visualization of large telemetry datasets for faster decision-making.

- Support remote operations: Design a platform that can be developed, tested, and deployed completely remotely, addressing the challenges posed by the COVID-19 pandemic.

- Ensure cost efficiency: Deliver the solution within the allocated budget while maintaining high quality and functionality.

- Achieve rapid time-to-market: We spent 4 months conducting research, so when we started the actual work on the project, we had only 8 months to complete it.

- Increase experiment throughput: Enable researchers to perform up to 2.5 times more experiments within the same timeframe through automation and parallelization of biochemical experiments.

The main challenge for us was to develop and launch the solution within the tight deadline and budget. To make this possible, we divided the development process into the following five phases: Discovery and requirement gathering; Solution design; Agile development & delivery; Quality assurance & testing; Deployment & support.

Solution

Within the agreed-upon time, we delivered a market-ready solution for chemists, hardware operators, project managers, technicians, and molecule designers that addressed the major client’s challenges through the following automated workflow:

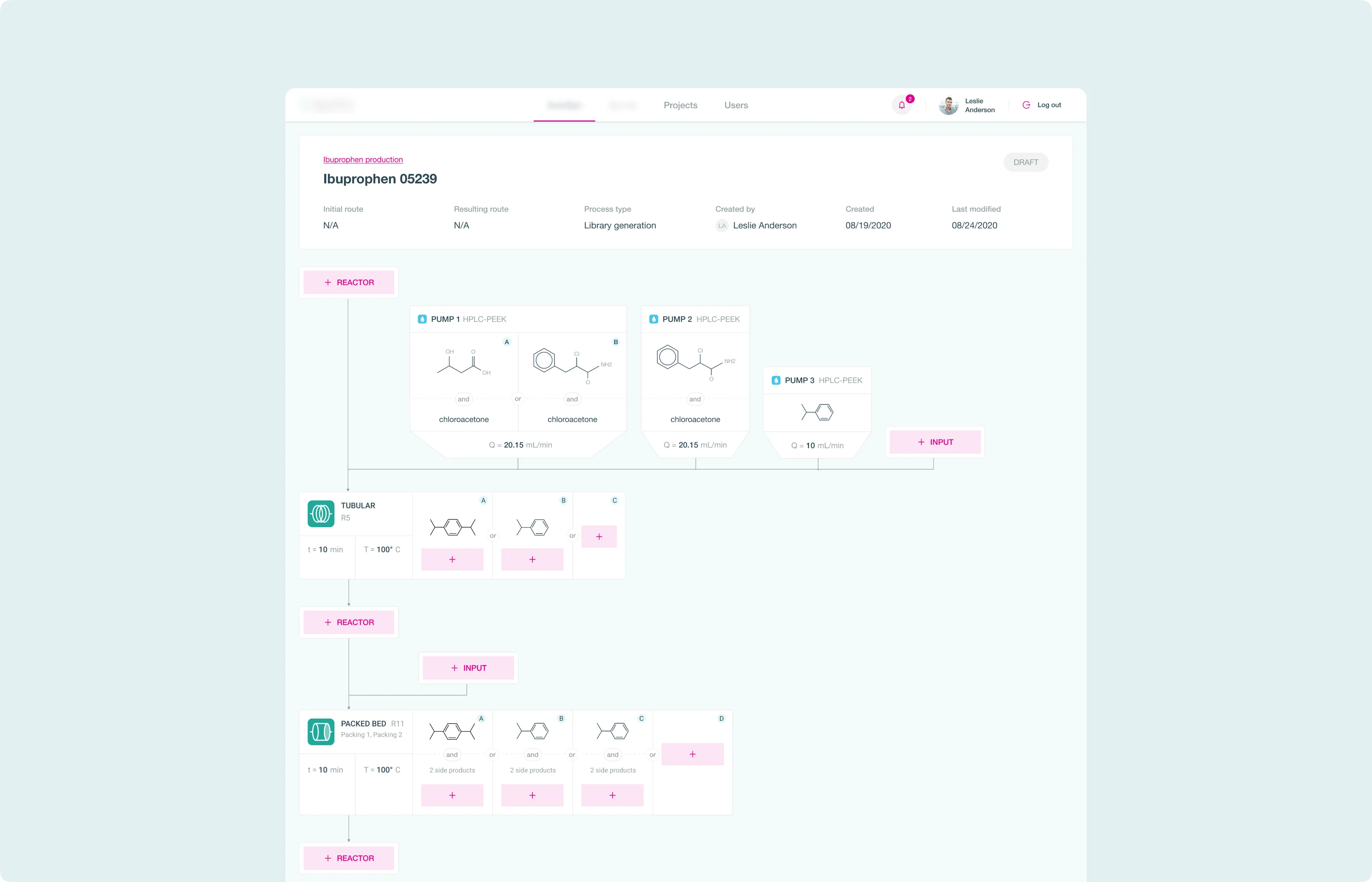

- Route Planning: The solution uses AI-driven algorithms to suggest optimal synthetic routes and cut the time and resources needed to design an experiment properly.

- Experiment Configuration: Scientists create JSON-based experiment configurations that the platform translates into robotic commands (such as ‘move the robotic hand,’ ‘pick up the vial,’ ‘load it with compounds,’ ‘put to mass-spectrometer,’ etc.).

- Automated Lab Setup: The solution integrates with proprietary robotic platforms to prepare experiments automatically.

- Parallel Experiment Execution: The platform runs multiple experiments simultaneously (up to five), maximizing hardware utilization and lab throughput.

- Real-Time Telemetry Collection: Hardware sends large-scale telemetry data, such as sensor readings and process metrics, back to the platform.

- Mass Spectrometry Integration: Analytical results from mass-spectrometry devices are automatically imported to the platform, reducing manual data handling.

- Data Thinning & Processing: The solution processes and filters massive datasets in real-time to ensure efficient visualization and analysis.

- Automated Reporting: Processed data is converted into detailed reports and experiment summaries, enabling faster decision-making.

- Feedback Loops: Based on data insights, the system can suggest parameter adjustments or new experimental configurations.

- AI-Driven Insights: Automated insights help optimize synthesis routes, reducing the need for repeated experiments.

Additionally, the following key modules were implemented:

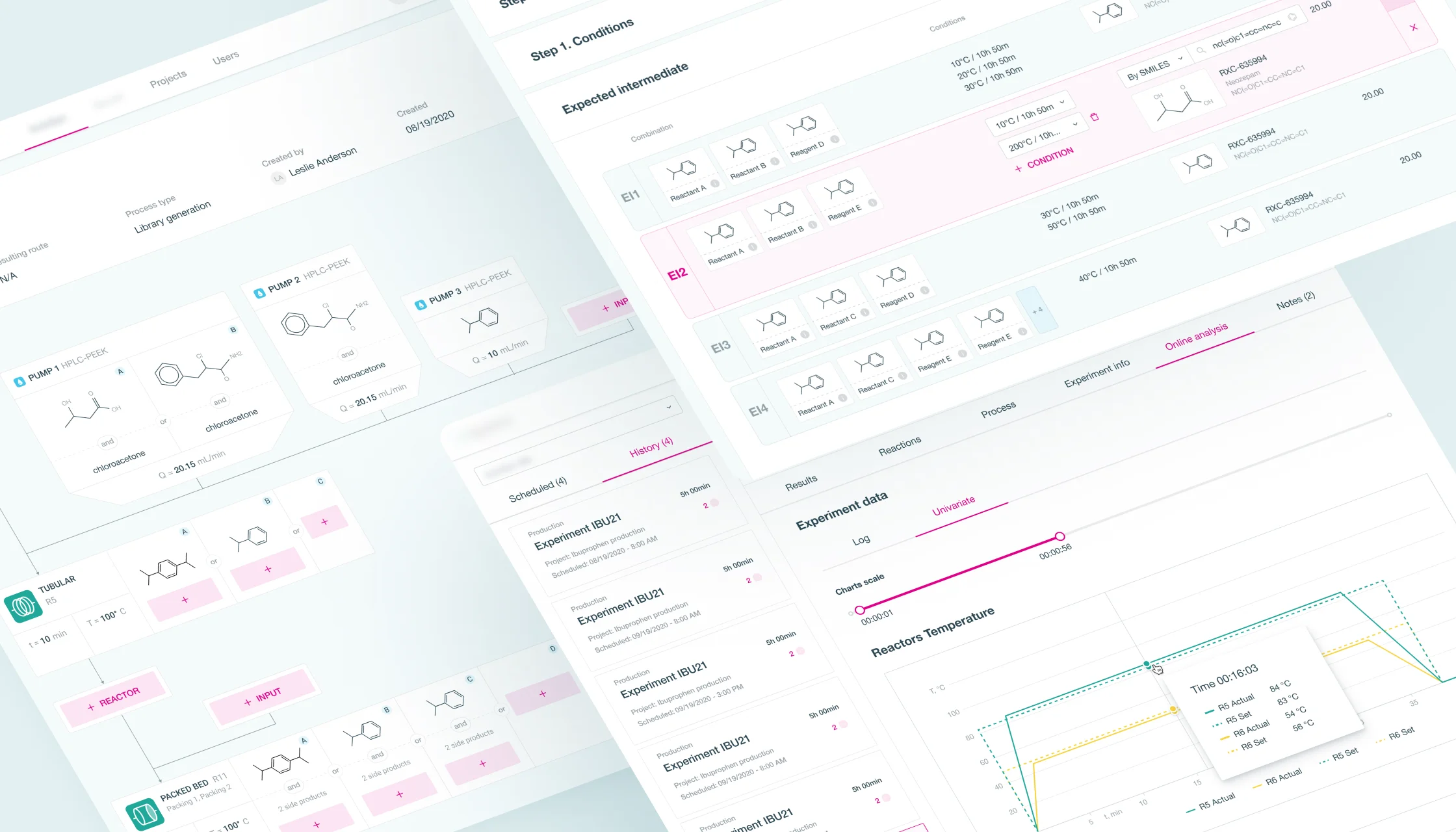

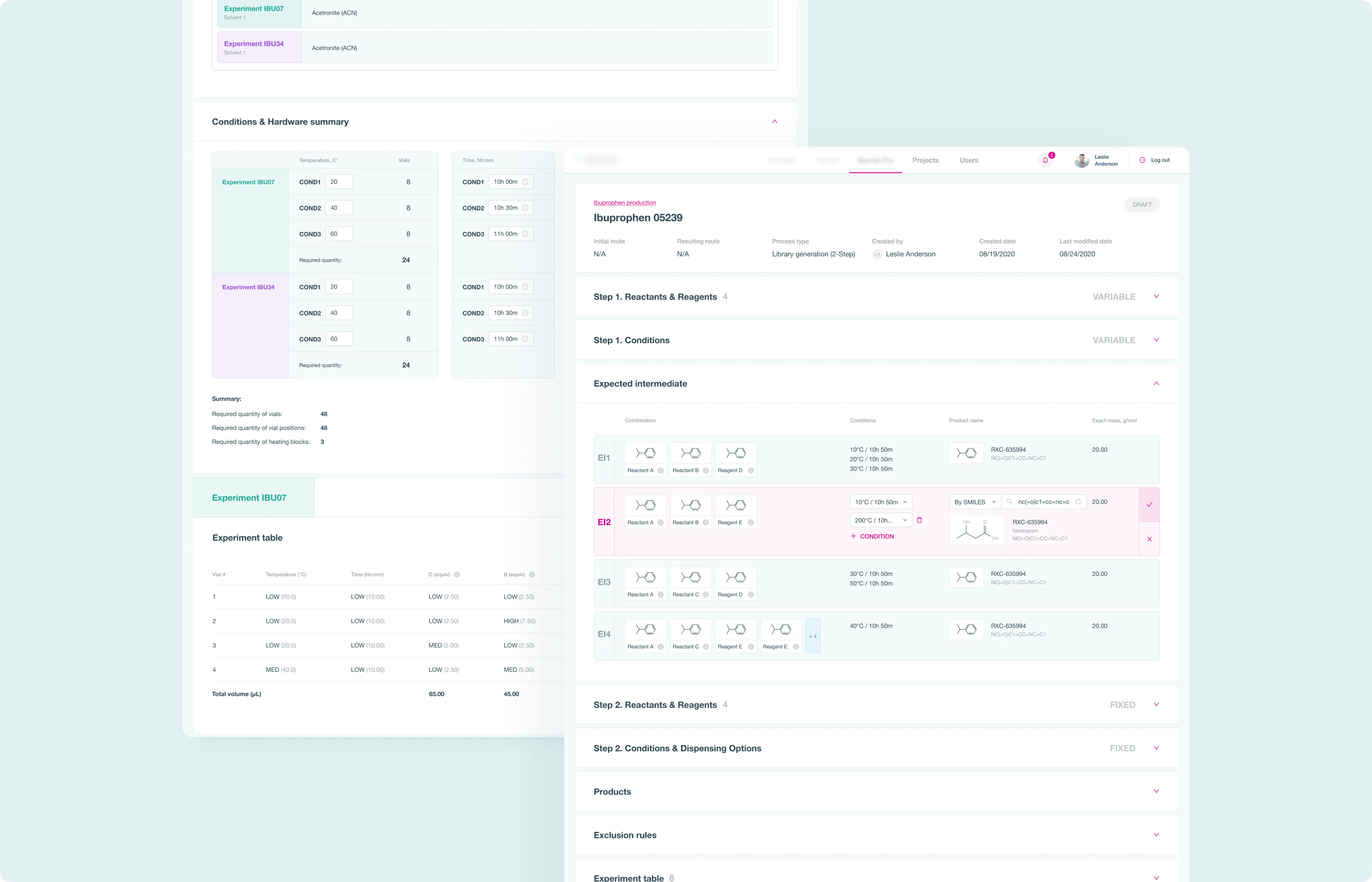

Synthesis Process Builder

A specialized interface for designing multi-step chemical synthesis processes tailored to the client’s hardware. It supports complex workflows by allowing scientists to configure continuous flow reactions, enabling precise and scalable experiment execution.

Reaction Screening Process Builder

An intuitive interface for designing reaction screening and optimization processes specific to the client’s hardware that the client already had. It allows scientists to define custom reaction conditions, enabling rapid testing and fine-tuning of chemical reactions.

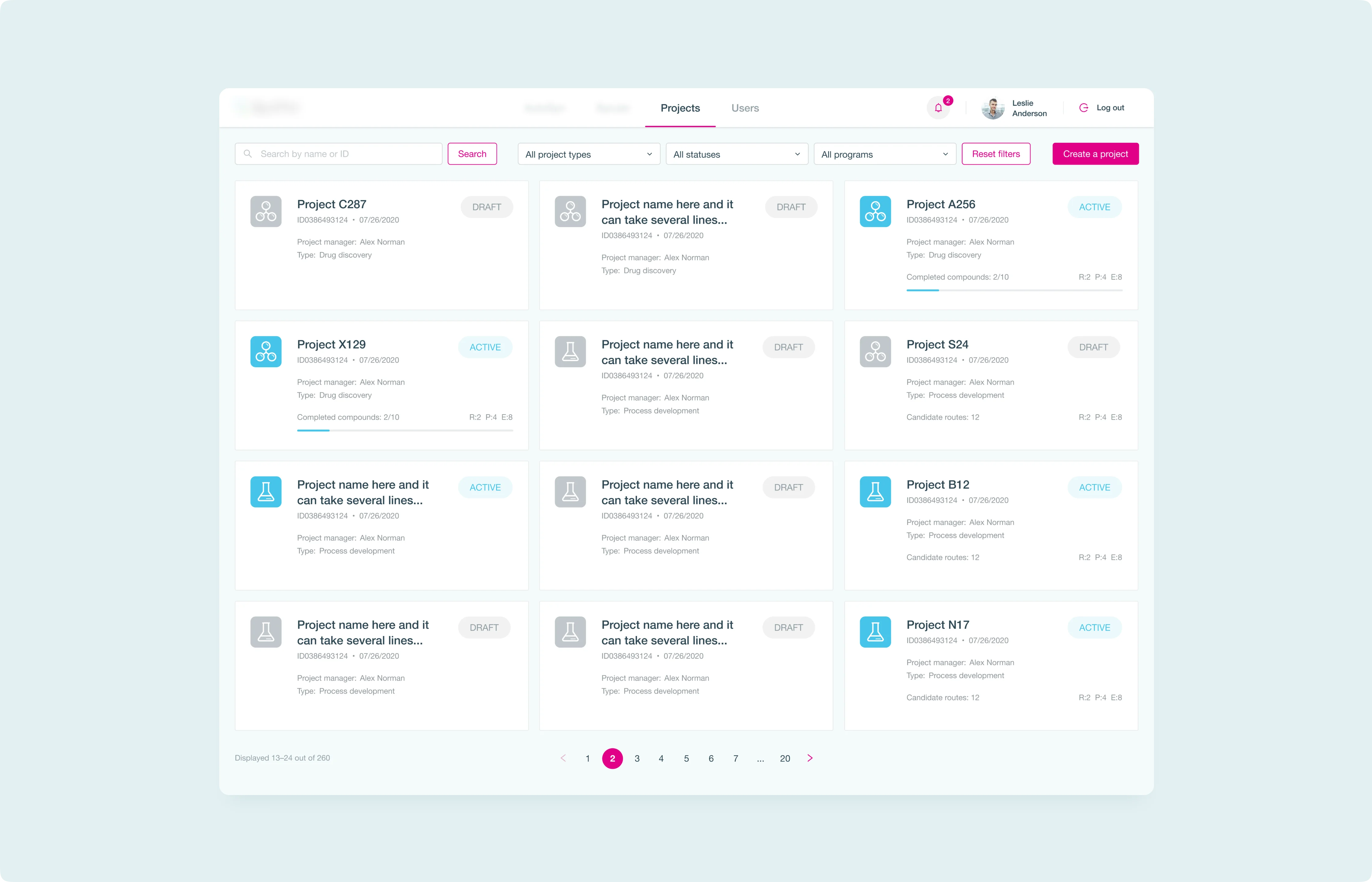

Project Management Module

A central hub for managing research projects, tracking experiment lifecycles, and coordinating team tasks. It provides tools for task assignment, experiment progress monitoring, and performance reporting.

Integration & molecule routes’ generation

An AI-driven module that generates optimal synthesis routes by integrating with molecular design tools. It computes chemical pathways considering hardware-specific capabilities, maximizing experiments’ efficiency and yield.

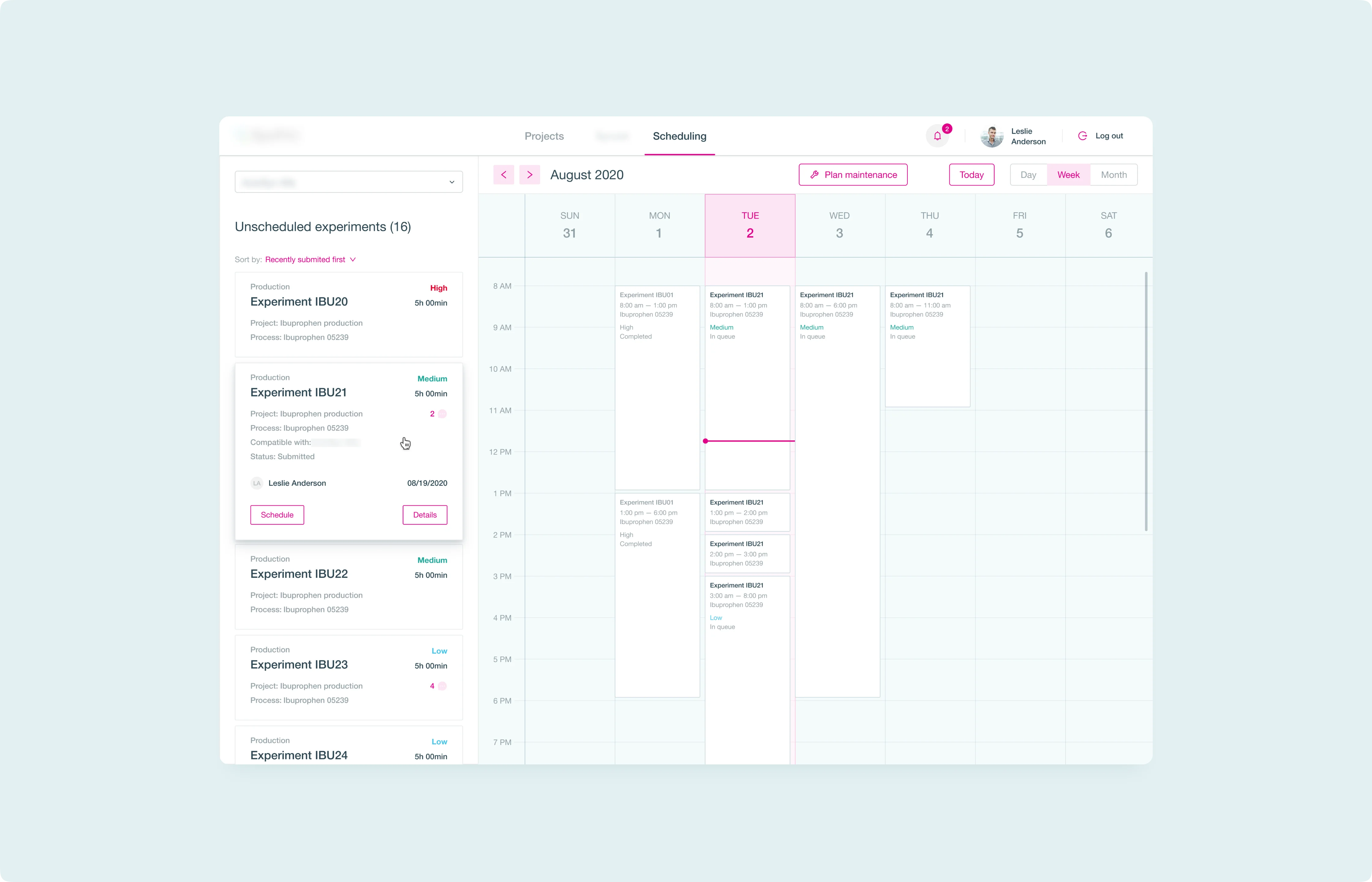

Experiments Scheduling Module

Manages the scheduling and sequencing of experiments across different robotic hardware platforms. It dynamically allocates tasks based on hardware availability and experiment priority to maximize system throughput.

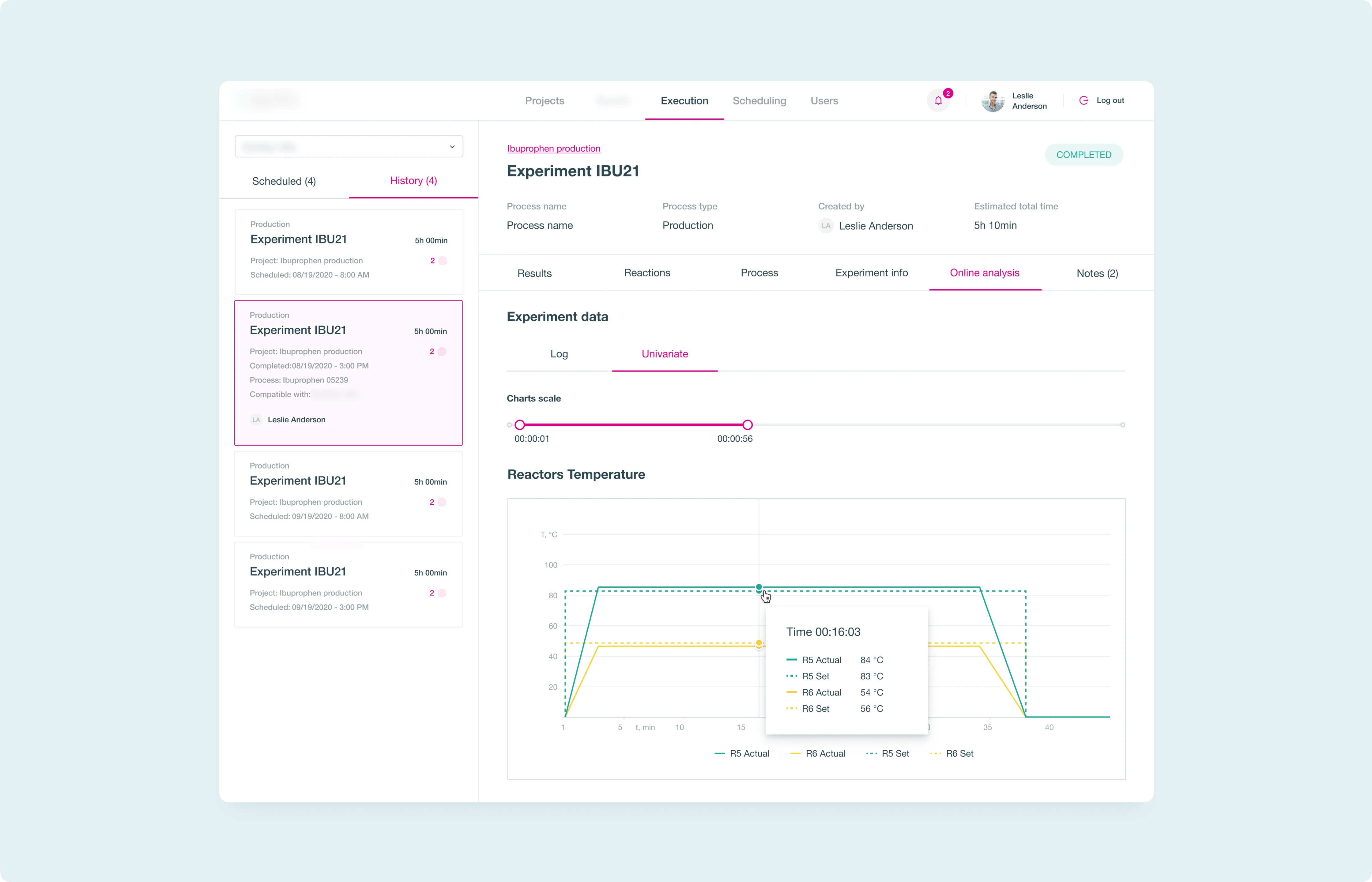

Experiments Execution Module

Orchestrates the execution of biochemical experiments by translating experiment designs into machine-readable commands. It ensures accurate hardware operation, real-time experiment monitoring, and error recovery.

Analytics Module

Processes and visualizes experimental data from sensors and analytical instruments. It offers real-time dashboards, trend analysis, and automated report generation for data-driven decision-making.

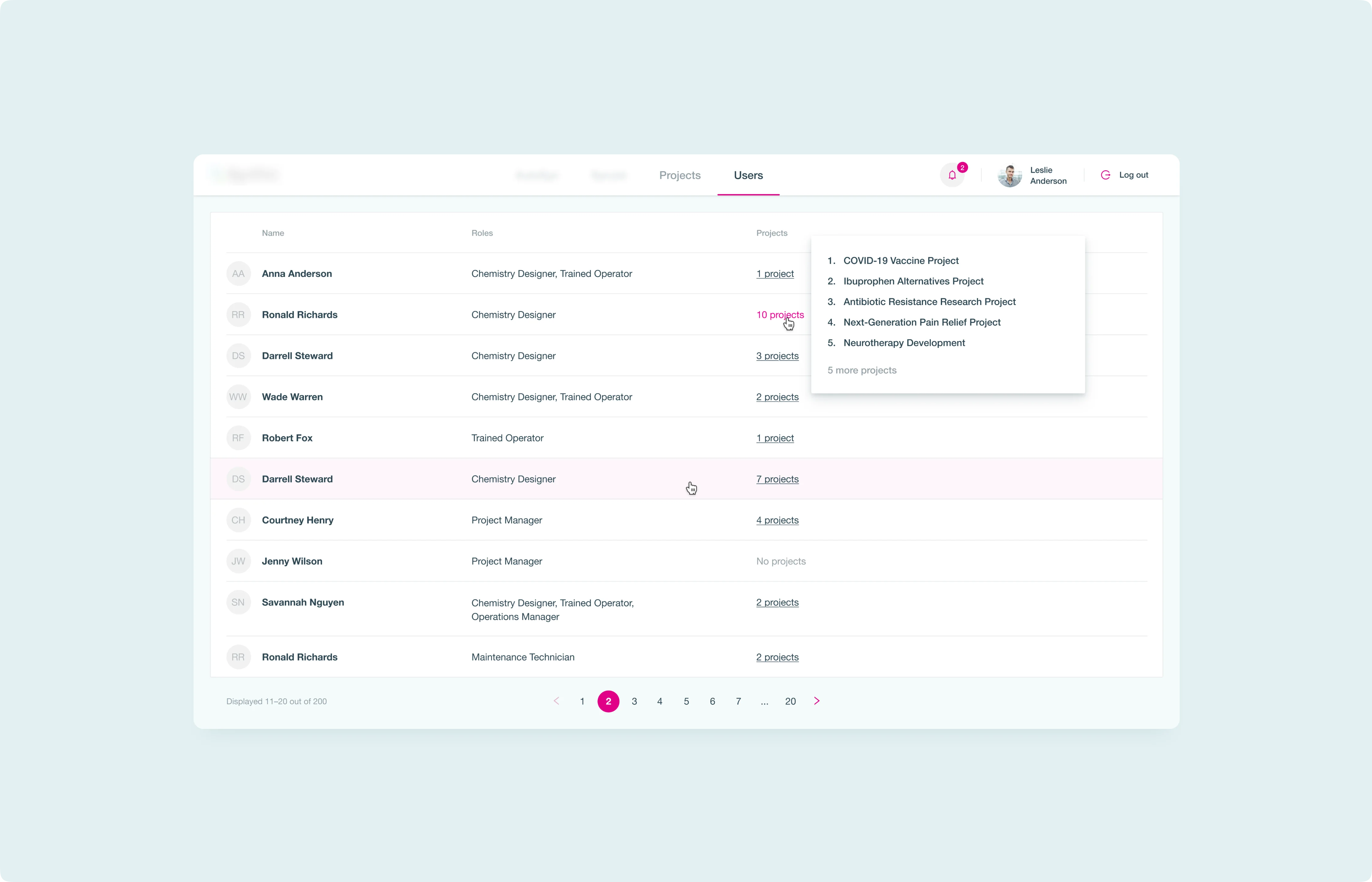

Administrative Module (user management, etc.)

Handles system access, user role management, and permission control. It includes authentication, authorization, and audit logging features to ensure security and compliance.

Technology Stack

Project Results

Emerline provided the client with a well-thought-out solution that allows automating biochemical experiments and receiving the necessary corresponding analytics data.

In particular, the client achieved the following results:

- Increased experiment throughput: Within the first six months after the solution’s launch, the number of completed experiments more than doubled due to workflow automation and parallel task execution.

- Accelerated time-to-discovery: Automated experiment design, execution, and data processing reduced manual work, speeding up biochemical synthesis cycles.

- Enhanced productivity: The platform’s scheduling and asynchronous task execution allowed up to five experiments to run simultaneously, maximizing hardware usage.

- Improved data accuracy & transparency: Real-time telemetry data collection, mass spectrometry analysis, and automated reporting minimized human error.

We continue supporting the release, providing documentation and training for seamless platform adoption and updates in new releases.

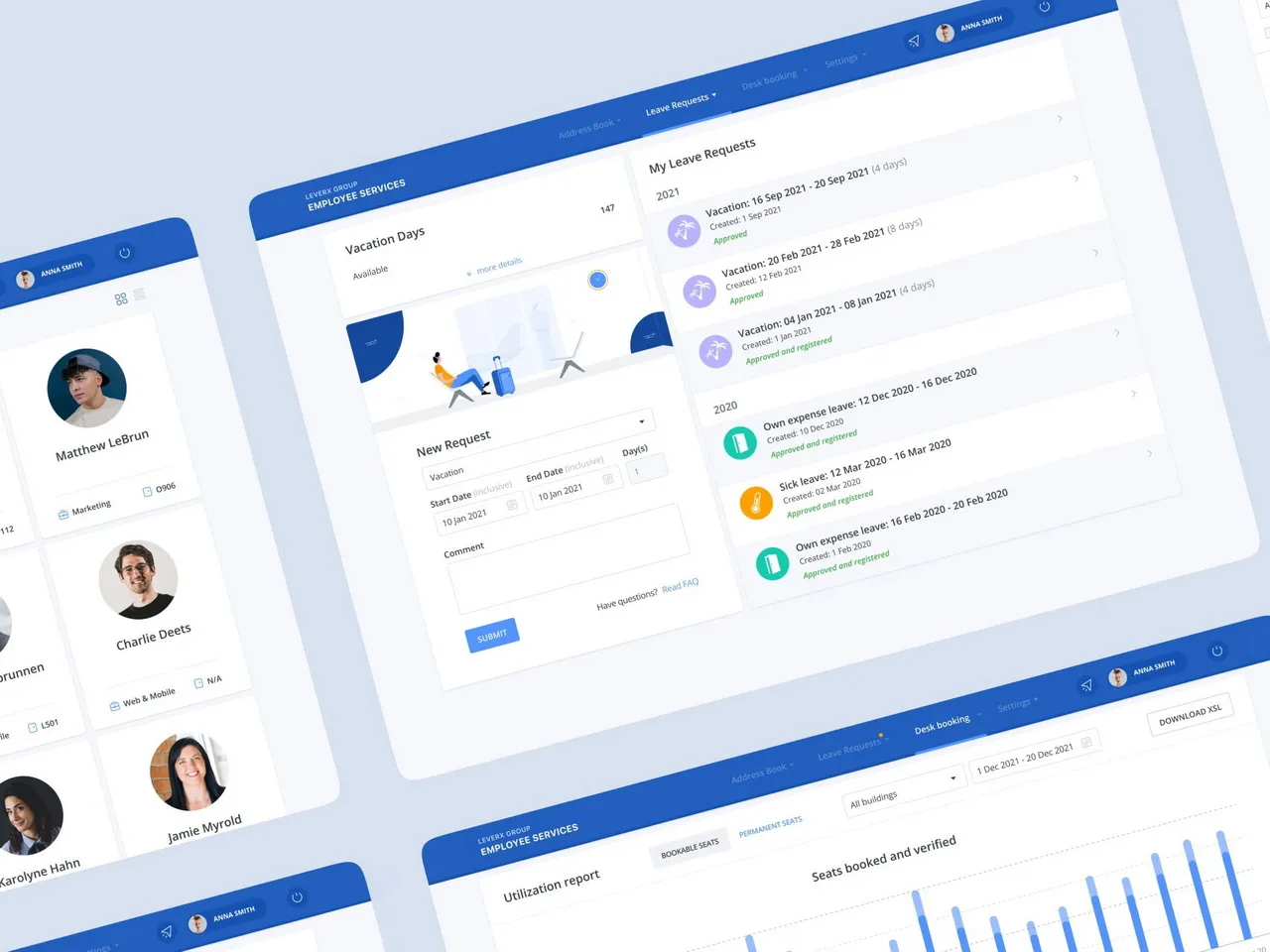

A desk-booking tool and inter-corporate solution for storing and managing employee data in one place. It allows companies with 1000+ employees to take full advantage of the hybrid work model and is friendly in use to both employees and HR managers.

Smart asset management platform for optimizing IT asset management in the companies big and small. It lets businesses monitor and manage all IT assets across company facilities, schedule equipment replacements, and automate routine tasks